The Best Ways to Use Lightweight Panels

May 7, 2024Lightweight composite panels are a popular and versatile tool in an architect, designer, or fabricator’s toolbox. From lightening the load on the road to elevating the aesthetics of the workspace, these panels offer endless creative possibilities.

In this blog, we’ll dive into panel preparation and some common areas in which they really shine.

Preparing Your Lightweight Panels

First, it starts with the materials — lightweight panels can consist of a variety of materials. Once your materials are selected, you should also consider a few methods that increase the adaptability of the panels to different construction needs and designs.

Selecting Materials

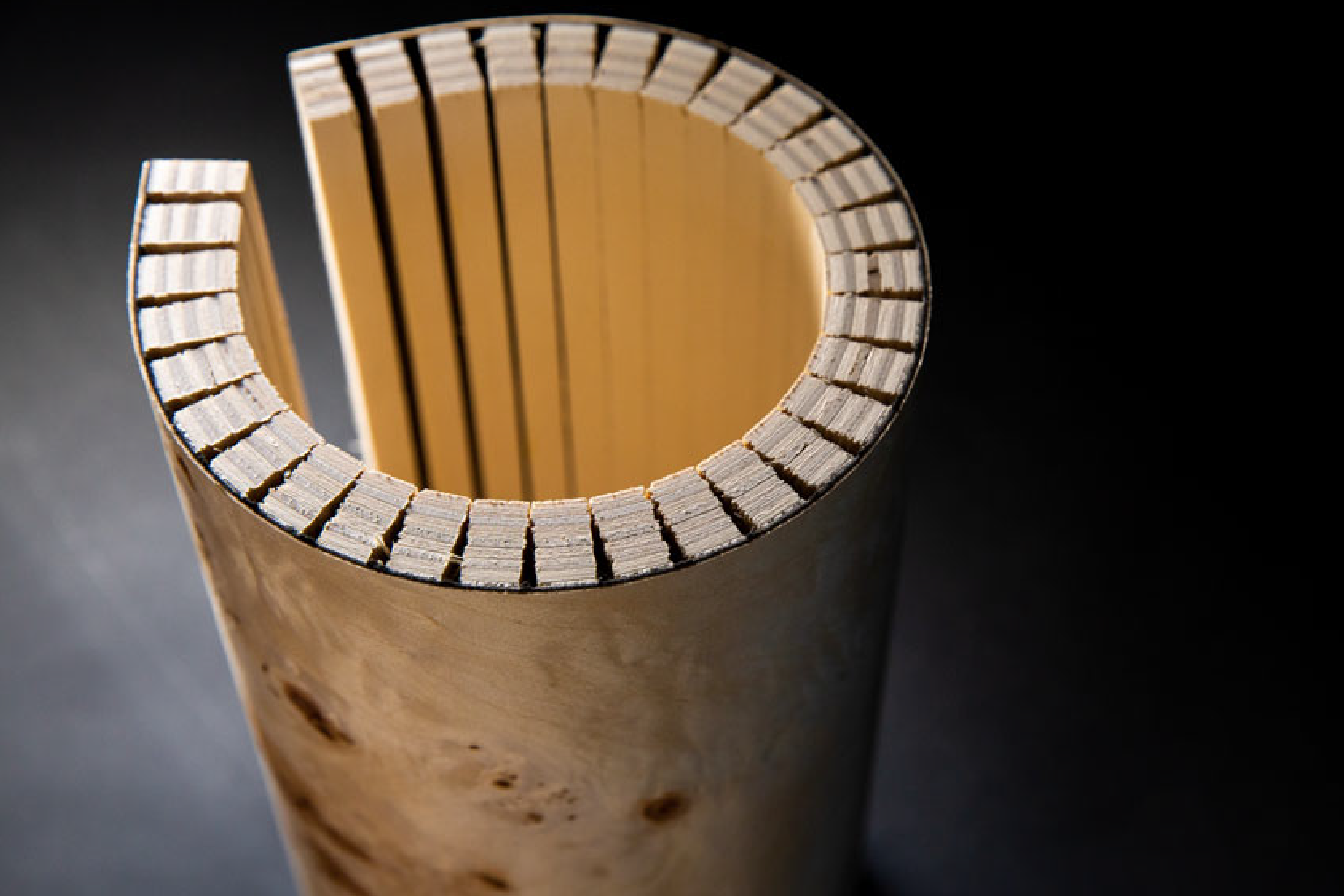

True to their name, sandwich panels consist of a core material sandwiched between two sides of face material.

Common face materials:

- High-Density Fiberboard

- Medium Density Fiberboard

- Plywood

- Hardboard

- Cardboard

- Metal

- Polycarbonate Plastic

- High Performance

- Carbon Fiber

- Fiberglass

Common core materials:

- Foam

- Honeycomb-shaped cardboard or polymers

- Wood

Finishing Your Lightweight Panels

Once your materials are selected, you can venture into finishing. Many panels are built to be decorative, making the finishing process key to getting the most eye-popping or aesthetically pleasing designs.

Common finishes:

- Laminates

- Veneers

- Paint

- Stain

- Metals

- Leathers

Internal Banding, Edgebanding, and Framing

The following methods are all different ways to make the already very versatile lightweight panels even more adaptable.

Framing

The framing refers to additional material or support around the outside of the panel. It is used to attach the panel to other materials or structures.

Internal banding

Internal banding refers to reinforcing the panel on the inside, to increase stability and strength.

Edgebanding

Edgebanding covers the edges of your panels, giving them a seamless appearance from the faces to the sides. It also improves the durability of your panels by protecting the exposed core from the elements.

Lighten Up Interiors

One of the most popular ways to leverage the aesthetics and accessibility of a lightweight composite panel is in interior design. Instead of plain, flat walls (ick!) these panels can deliver a pop of interest and complement a modern or classic interior design, with wood paneling or fluted designs.

Thanks to their light weight, composite panels also make it easy to transform the ceiling of an interior space. Maybe you used a painted finish for a room’s walls and now want to add contrast with a wood finish ceiling. Or you can use the paneling to match the ceiling and walls to create a cohesive design throughout the entire space.

Or maybe, you want to get even more ambitious like the Kerfkore customers pictured below.

Oversized, Yet Still Lightweight

At Kerfkore, we say that lightweight sandwich panels are made for the three Os: overweight, oversized, or overhead. Each situation goes from headache-inducing to creative serenity when leveraging easy-to-use lightweight panels.

Speaking of oversized, we’ve built custom doors with lightweight panels. This can be useful in large spaces such as museums where the door needs to fill a large frame without becoming too heavy.

Transform Transportation with Lightweight Panels

Lightweight composite panels can be used in RVs, vans, and any other vehicle that needs interior modification without adding too much weight. Over recent years, there’s been a surge in popularity in traveling and living out of a van. As DIYers and commercial conversion companies add interior structures like cabinets, these panels are popular due to their ease of use.

Furnish Furniture

Lightweight panels are ideal for crafting custom furniture pieces that are both stylish and functional. For example, designers can use them to create light yet sturdy tabletops, shelves, and cabinets. These panels allow for beautiful designs and can be easily customized to meet specific aesthetic and functional requirements. They also facilitate the creation of movable furniture pieces, making them popular choices for modern, adaptable spaces.

Elevate Your Next Space With Kerfkore’s Lightweight Panels

At Kerfkore, we manufacture our line of Worklite panels that reduce material weight up to 80% by capturing a lightweight core between two thin high-density faces, resulting in a strong lightweight panel with structural integrity. Contact us today for more information or help with working with our architectural panels or check out our Worklite Buyer’s Guide.