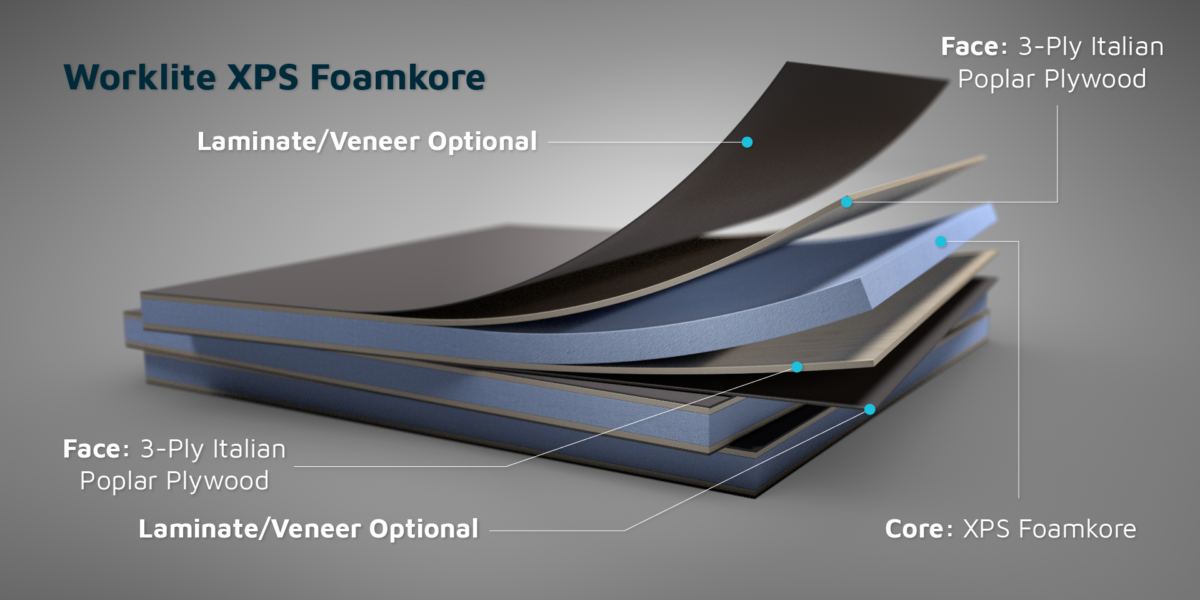

WORKLITE® XPS FOAMKORE®

Our Worklite XPS Foamkore lightweight panel reduces material weight up to 80%* by capturing a lightweight core between two thin high-density faces, resulting in a strong lightweight panel with structural integrity. Core material is a dense closed-cell Styrofoam that provides moisture resistance, thermal performance and compressive strength. Some panels can weigh as little as 12 oz/sf while still providing a 1/8″ plywood faced panel to achieve a 3/4″ overall thickness. Panels can be covered with high-pressure laminates, veneers, metals and many other semirigid materials as well as stained or painted.

*Compared to conventional panels made of plywood, particleboard and MDF

Face Materials

Eucalyptus Hardboard (Standard)

Fiberboard

3-Ply Italian Poplar Plywood

Core Materials

Extruded Polystyrene (Standard)

Fire Rated Option

Extruded Polystyrene

Flame Spread Rating: ASTM E 84: Class A (core only)

Flame Spread Rating: ASTM E 84: Class A (core only)

Sustainable Options

Eucalyptus Hardboard Face

Nominal Thickness

| 1/2" | 5/8" | 3/4" - 3" | ||

|---|---|---|---|---|

| Extruded Polystyrene | ||||

Panel Sizes

| 48" x 120" | 48" x 144" | 48" x 96" | 60" x 144" | ||

|---|---|---|---|---|---|

| Extruded Polystyrene | |||||

Decorative Surfacing Materials

High Pressure Laminates

Veneers

Metals

Paint

Adhesive Option for Lamination

Contact Adhesive

Recommended when using a J-Roller

PVA Glue

Recommended when using a Press Machine

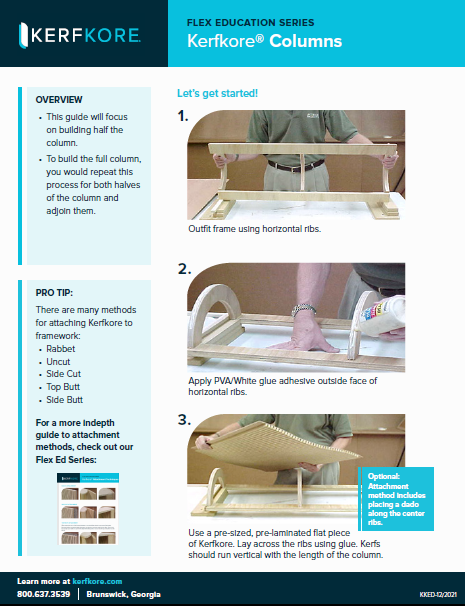

Attachment Methods

PVA glue or staples recommended