Fabricating Flexible Wood Panels: Kerfkore VS. CNC Machine

April 27, 2023

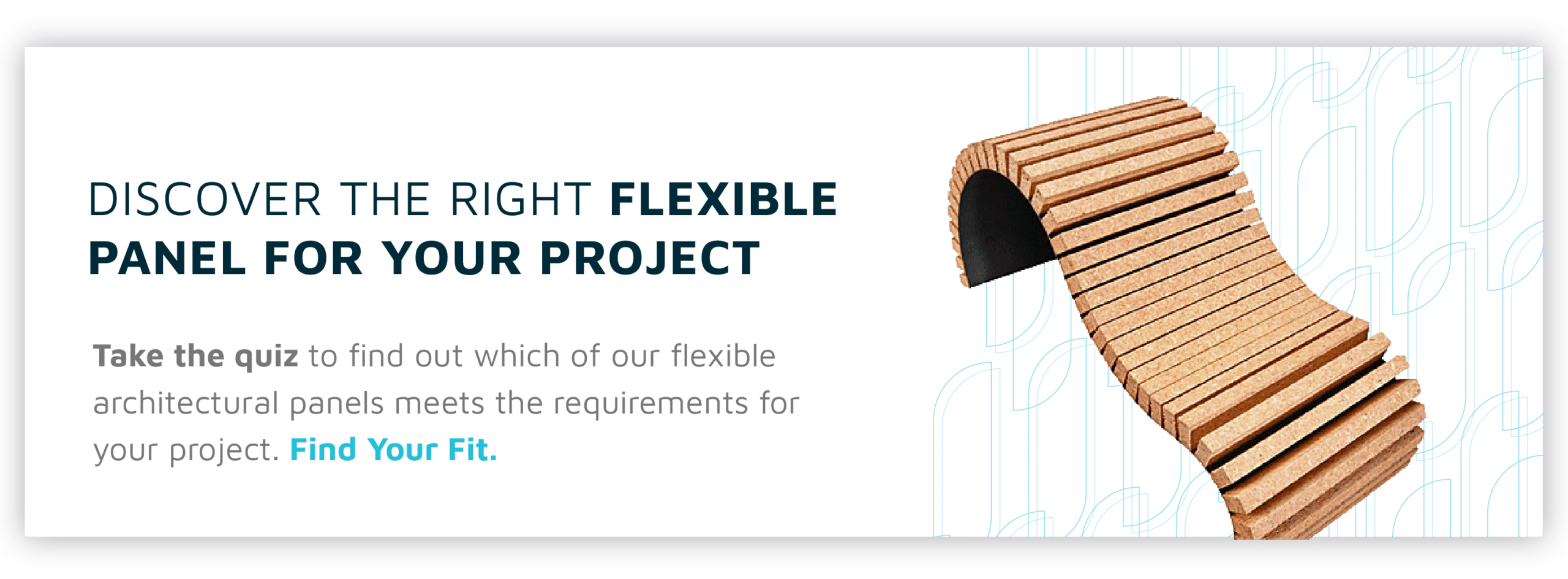

Creating flexible or curved wood panels is a creative way to add a dynamic, yet natural-looking aesthetic to interior design or architectural projects. If you’re working on a project that requires a flexible wood panel, or a project where a curved wood panel would really make it stand out, you have a few methods to consider.

In a previous blog, we touched on one of the most popular options for flexible wood panels in bending luan. Bending luan is an inexpensive, flexible type of wood but has issues with reliability, quality, and appearance, and may be best suited for simple DIY projects.

Other options for creating curved wood include kerfing in-house or steam bending, both of which may be appropriate for smaller projects assuming one has the resources and capability but can get quite tedious as your project scales larger.

Today, we’re going to discuss using a CNC machine to kerf panels and how it compares to adding pre-engineered flexible panels like Kerfkore to a design project.

CNC Machine for Kerfing vs. Kerfkore Flexible Wood Panels

CNC Machines are a popular tool in the architectural and interior design realm. They are incredibly consistent, which makes them valuable for high-volume production, and are capable of achieving a high degree of precision for intricate designs.

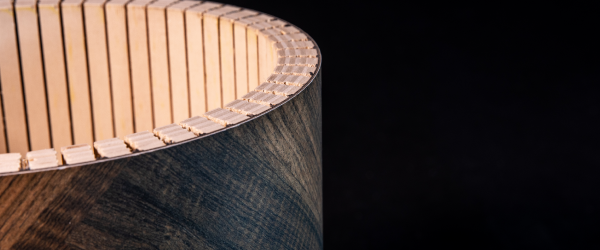

On the other hand, Kerfkore’s flexible pre-engineered panels are specifically built and designed for various types of radius projects; bending tighter, with more consistency and dimensional stability than traditional products.

Keep reading to find out why pre-engineered panels like Kerfkore may be your best option when it comes to cost, time, and quality— even if you have a CNC machine available.

Cost

If you don’t already own a CNC machine, purchasing one may pose a large barrier to entry. High-grade CNC machines are expensive. There are cheaper CNC machines available, but those are typically used for hobbyists tinkering in their garage, or one-off proof of concepts. In order to achieve production-level quality, it’s not uncommon to spend $100,000 on a CNC machine. The highest quality, state-of-the-art CNC machines can cost up to $500,000.

That cost doesn’t include the space required to house a CNC machine, regular maintenance, hiring a CNC operator, and the extra costs of buying an expensive piece of manufacturing equipment, such as software and additional tools.

Speaking of maintenance and additional tools, kerfing is hard on a CNC machine. The multiple passes required to achieve a desired depth means more wear and tear on the CNC machine’s blades.

Another option is outsourcing your work to a CNC machine shop which alleviates the upfront expenses but can still be quite costly. Outsourcing in the United States can cost anywhere from $40 per hour to $100 per hour and varies widely in speed and quality.

At Kerfkore, we keep it simple. Instead of considering the many variables and costs of outsourcing to an expensive shop or purchasing a CNC machine yourself, we offer straightforward, standardized pricing for your flexible panels.

One of the biggest concerns companies have when determining how an architectural panel project will be executed is trying to estimate the costs associated. We’ll give you one, consistent price so you can budget up-front and know whether a project will be profitable or not.

Quality

Overall, CNC machines are known for their incredible precision and consistency, but when it comes to the art of kerfing, they can leave a bit to be desired.

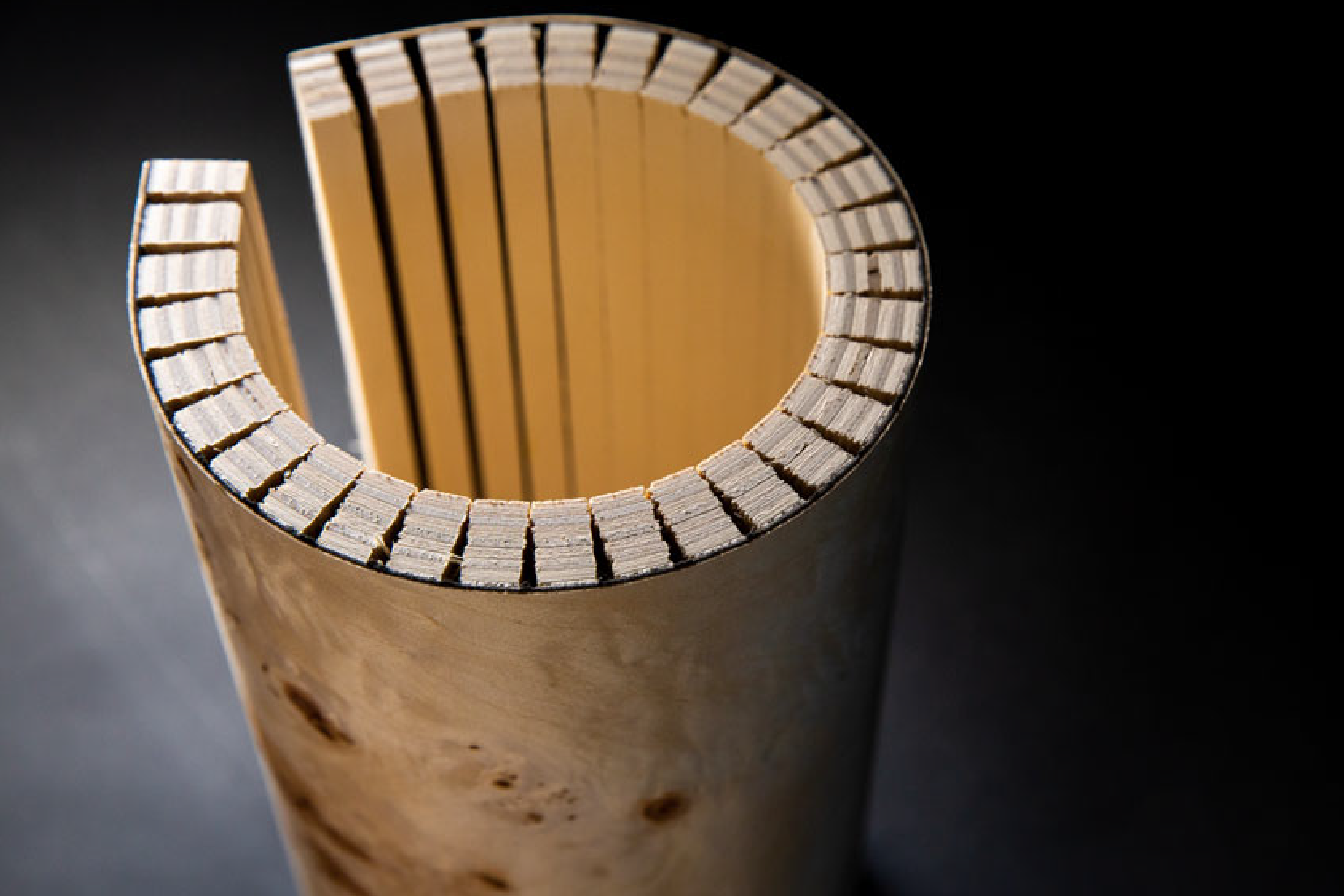

When a CNC machine is creating kerfs it can only achieve a partial cut, which can lead to telegraphing. Telegraphing is where the wood pattern or grain can be seen through the finish. Unless specifically asked for, telegraphing can make a product unusable.

With Kerfkore products, you’ll receive smooth faces and high-quality consistent results with no telegraphing thanks to our precise manufacturing process. And Kerfkore panel cores come specifically cut to provide stability.

All of our panels are engineered with carefully selected, high-quality materials that are less affected by changes in moisture compared to traditional products.

Time

With many companies still struggling to hire help, time is an incredibly valuable resource.

CNC machines save time when compared to the processes and early machine tools they helped replace, but as illustrated above, CNC machine users will have to invest plenty of time into researching the purchase and implementation of a CNC machine.

Included in the implementation of a CNC machine is time spent performing specialized programming, calibration, regular maintenance, and tool changes.

When using a CNC machine for creating kerfs, users will have to determine the exact amount of kerfs needed and the precise spacing between them to achieve a desired bending radius, a tedious and timely process.

With Kerfkore panels, you can simply tell our team what type of radius is necessary, and we’ll provide the perfect Kerfkore product for your project. Beyond saving time creating the panels, Kerfkore also ships products ready for installation, eliminating time spent on tasks like sanding or applying Bondo. Avoiding extra time spent on fabricating and installing can be a huge boon to teams already spread thin by the current labor shortage, and frees up CNC machines for other tasks— making your output more efficient.

Overall, the CNC machine is an incredible manufacturing tool, but it requires an incredible investment of time, money, and resources to utilize to its full potential. One of its strengths is its versatility, but a jack of all trades is a master of none— in order to receive architectural panels built for your exact project and achieve masterful designs, speak with a Kerfkore sales rep today or request your free sample kit today.