Save Material Supply & Employee Time with Soflex

January 5, 2022Last month, we interviewed industry experts to identify the biggest trends in the architectural panel industry. Again and again, issues affecting the supply chain like lack of materials and the labor shortage were brought up. Fabricators should prepare to make the most of their resources going forward as experts in all industries are unsure if the supply chain blues will get worse or better in 2022.

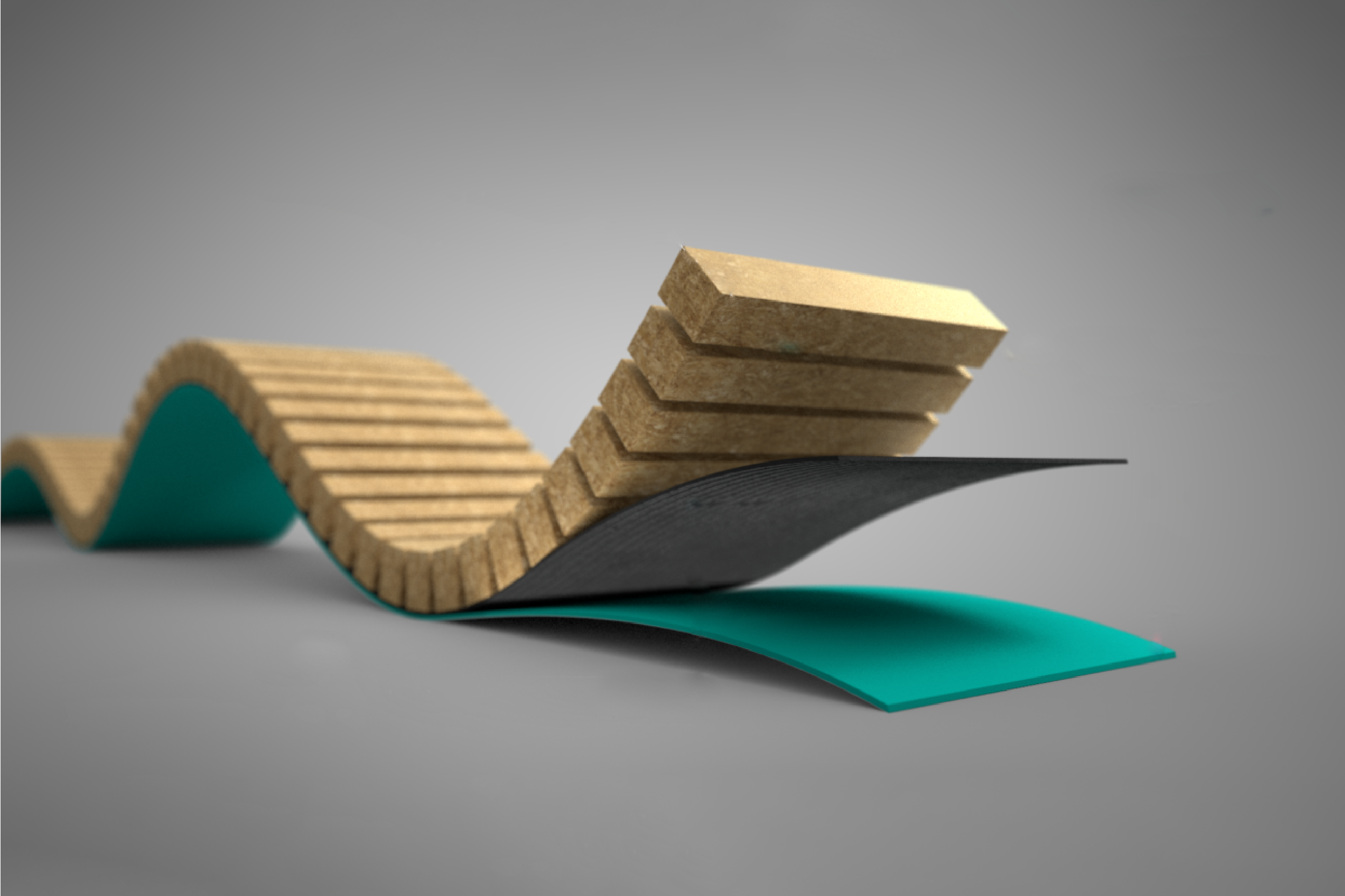

Luckily at Kerfkore, resourcefulness and flexibility are in our name. Our Soflex product requires less surface preparation, structural framework, materials, and installation time. Here we’ll break down some of the biggest ways Soflex saves you time and resources. Note: Soflex was previously called Kerfkore. We updated the name in June 2024 to differentiate the panel from our company name. It’s the same great panel, with an updated name!

Save Resources with Easy-Splice

A simple way to maximize your Soflex panel is with a technique called Easy-Splice. Easy-Splice is a method of joining two pieces of Kerfkore together, end to end. This way, you can make smaller pieces into larger pieces, either in width or length. This eliminates scrap, uses 100% of the material, and is completely unique to the Soflex product.

How does Soflex exclusively offer Easy-Splice? It’s thanks to its LTX Black Flexible Backer. This backer allows us to laminate our product flat, then form.

To begin splicing we lay out all of our separate Soflex pieces in the shape of our desired design. We then size and apply a laminate over all of the pieces, rather than gluing them together since the laminate forms the adhesive. Now, all of those spare pieces of Soflex from your last project that you would normally scrap can now be used for your next project. Also, unlike plywood this Soflex technique allows you to create the exact size panel you need, eliminating unnecessary waste.

Don’t Waste Time Kerfing by Hand

Kerfing by hand isn’t easy. Not only is it extremely time-consuming, which ties up one of your most valuable resources, manpower, but it’s also easy to botch. Each cut has to be just deep enough to allow the wood to bend but not so deep you’ll cut through. A precarious balance that must be found countless times, depending on the size of the wood. You’ve heard of the phrase “death by a thousand cuts” but kerfing by hand is more like “boredom by a thousand cuts.”

When you kerf by hand you’re leaving your project to the mercy of human error. Without precise kerfing, there is likely to be variation in the distance between cuts and the depth of cuts. Variation can lead to a few notable issues:

- Kerfs telegraphing to the surface

- Varying flexibility

- A radius that will be difficult to maintain

- An uneven surface that will require additional treatment

Some fabricators will suggest using a Computer Numeric Control (CNC) Machine, a computer-controlled router that can cut and carve wood, rather than kerfing by hand. Like kerfing by hand, this process also isn’t ideal for most projects. If your company has a CNC Machine, it’s likely that it was bought for more important processes than kerfing, not to mention that kerfing can put a lot of unnecessary wear and tear on expensive CNC Machines.

Spend Less Time on Fabrication

One of the biggest ways Soflex saves time is that it requires very little to no sanding or use of putty. Thanks to Soflex’s LTX Black Flexible Backer it easily attaches to high-pressure laminates, veneers, metals, leathers, and other semirigid materials. Unlike bending plywood, Soflex requires no special care or maintenance. Once it’s installed you can stop worrying about extra steps or delegating additional labor to the maintenance of your project.

Need further convincing of Soflex’s resource and time-saving abilities? Here’s Walton Scott from Quality Cabinet & Fixture Company in San Diego, California on his experience using our products, “The Kerfkore product line allows our team to focus on what they are really good at doing, rather than dedicating an excessive amount of wasted time on unskilled administrative tasks such as sanding, filling flat areas with Bondo and unnecessary framework. This allows us to offer a better price to our customers.”

Soflex allows your company to use its time, people, and resources more efficiently, whether the labor shortage or supply chain issues continue or not. Soflex panels arrive ready for installation, saving time. Easy-Splice allows you to use almost the entire panel board, saving resources. And your employees don’t have to spend time on menial fabrication tasks, freeing them to focus on the projects that really matter. Want to see for yourself? Request a sample and see the difference in person.