Kerfkore vs. Bending Luan Plywood

August 3, 2022Bending luan is one of the go-to choices for fabricators, DIYers, and many wood-based hobby enthusiasts. Due to its relatively low price and versatility, luan has become popular enough to earn quite a number of nicknames including wiggle wood, bendy wood, snakewood, meranti, Lauan, Philippine mahogany, and our favorite – wacky wood.

As its colorful nicknames imply, luan possesses properties that allow the wood to be bent and curved. Of course, as we outlined in a previous article (and as the name wacky wood would suggest), its bending is unpredictable. This can lead to issues with reliability, quality, and appearance. It’s not just its unpredictable properties that cause problems either. There are concerns about the amount of time needed for preparation, the bending process, the cost, and the sustainability of luan.

Our Kerfkore products can solve some of the biggest issues of bending luan. Let’s dive into each of the above issues to see how Kerfkore stacks up.

Quality

We briefly touched on the unpredictability of luan plywood, but it’s also limited to the degree to which it can bend. Bending luan typically comes in very thin sheets, which means projects may require multiple sheets stacked, and the quality can vary from sheet to sheet. This leads to a lot of trial and error and broken luan boards for fabricators, as they try to achieve their desired bend radius.

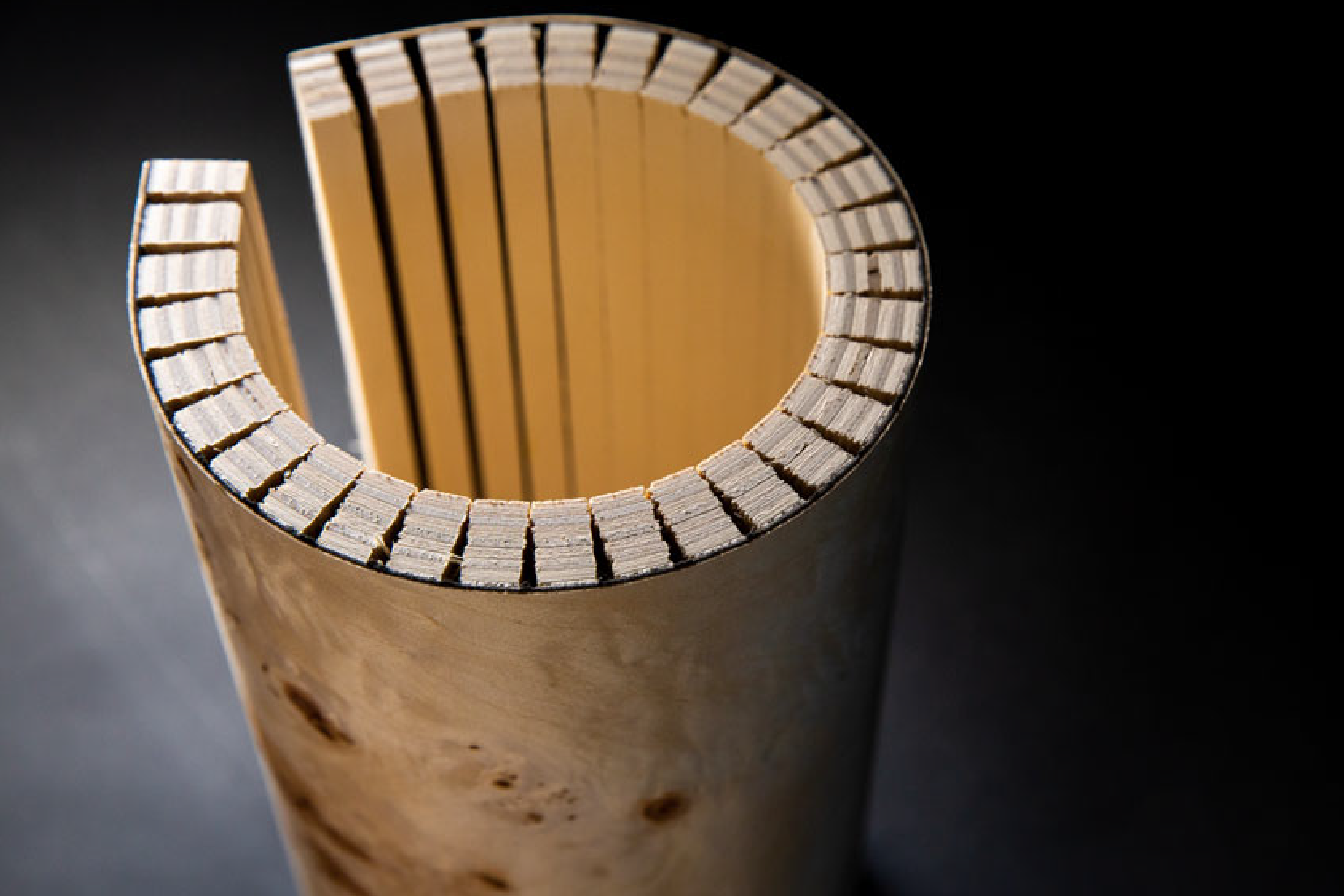

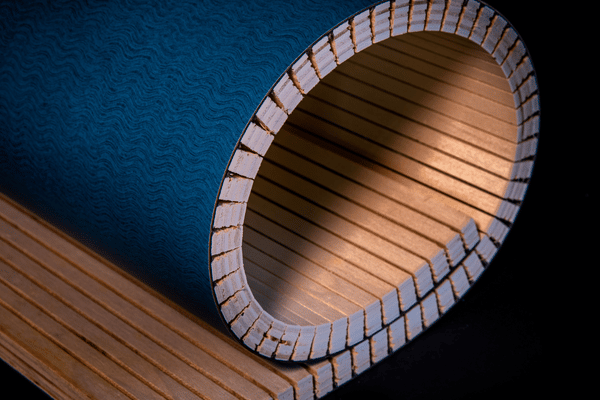

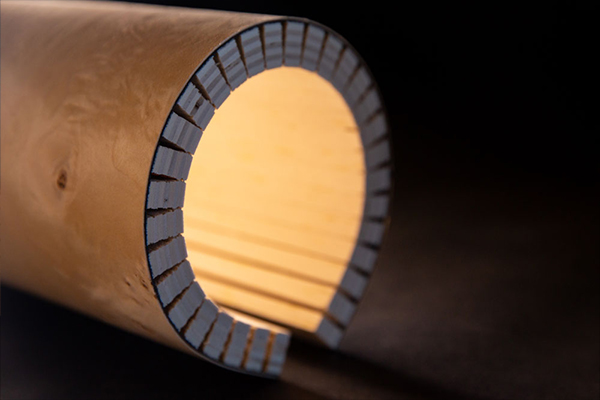

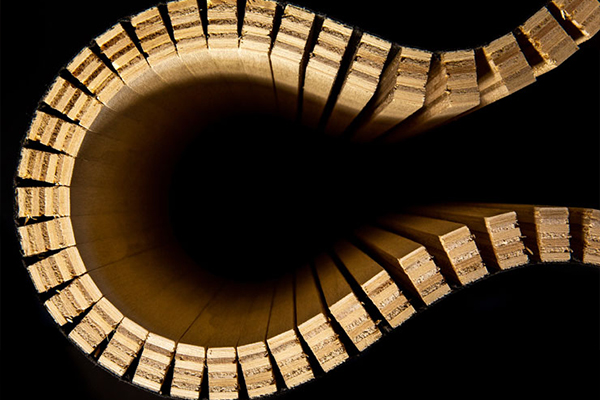

Kerfkore, on the other hand, is extremely flexible and can achieve a tighter bend radius than typical luan – up to a 3 ½” dynamic bending radius.

Kerfkore products come in a wide variety of standardized thicknesses and provide superior strength and durability compared to luan.

Kerfkore products can also easily attach to high-pressure laminates, veneers, metals, leathers, and other semi-rigid materials. And some Kerfkore products can even be laminated flat or curved, which gives fabricators more flexibility when working on a project.

“While we have made curved pieces with bending board and veneers previously this was our first attempt at building something with this kind of shape. I found the Kerfkore to be easier to work with than I expected. I don’t know if I could have or would have wanted to build this the old way. We did additional supports inside which I understand is overkill with Kerfkore. I would feel comfortable doing more shapes with Kerfkore in the future.”

BRYAN EADS | THE BOOKCASE PLACE OF RICHMOND, INC.

Time

It’s not just the high variance of luan’s flexibility and quality that can trouble fabricators, luan plywood also requires a considerable amount of preparation for bending/finishing, as well as the necessary time, equipment, and know-how to execute the bend.

There are different techniques to create a bend in luan, including clamping or strapping the wood, but each requires the proper equipment and technique.

When attaching luan, the necessary framework requires a lot of vertical ribs to minimize imperfections, like cracks and dips, on the surface. Kerfkore requires a much simpler framework. Your framework will rely mostly on horizontal ribs, vertical ribs will only be needed for positioning the horizontal ribs or providing a vertical seaming rib.

Once the luan sheet is attached to your framework, you’ll still need to prepare for finishing. The open pore structure that allows luan to bend also creates small gaps. In order to cover these gaps or holes, luan must be sanded, patched, and possibly have Bondo applied. If the proper care and time are not taken, you may end up with a finished product with an uneven, curved surface.

Kerfkore products, on the other hand, come ready for simple prep and installation. Kerfkore features smooth facings, so decorative lamination is quick and easy, and never requires additional sanding, patching, or Bondo.

“[Kerfkore Products] provide stronger, better, and more reliable results compared to our old approach where we used layers of 3/8″ bendable plywood. The Kerfkore product line allows our team to focus on what they are really good at doing, rather than dedicating an excessive amount of wasted time on unskilled administrative tasks such as sanding, filling flat areas with Bondo and unnecessary framework. This allows us to offer a better price to our customers.”

WALTON SCOTT | QUALITY CABINET & FIXTURE COMPANY (SAN DIEGO, CA)

Cost

For fabricators, one of the most attractive features of luan is its cost. While the price of raw luan plywood is relatively cheap, fabricators must factor in the time investment (and therefore labor hours) necessary to make luan suitable for bending.

Add in the unpredictability of the quality of the luan you’re purchasing (it may break or take 2 or more boards to reach your project’s ideal thickness) and it’s difficult to determine your project’s budget. With Kerfkore products, you’re given a standardized, upfront cost – which makes the overall cost of your project easier to plan.

Sustainability

Another concern that has historically plagued bending luan plywood is whether it can be sustainably sourced. At Kerfkore, we offer sustainable alternatives for the core of our products, such as NAUF Particleboard.

In addition, most Kerfkore products have low Volatile Organic Compound (VOC) content, are made from reclaimed and recycled materials, and contain no formaldehyde.

The original Kerfkore product also utilizes our Easy-Splice technique, which allows you to splice together scrap material, which means less waste.

While bending luan plywood can be the right choice for plenty of DIY projects, if your work calls for a professional touch, accurate budgets and time allotment, and a product you can be certain is eco-friendly – then Kerfkore products are the right choice.

Ready to experience high-quality Kerfkore products for yourself? Request a sample now!