Five Reasons It’s Time to Break From Luan Plywood

May 18, 2021Luan plywood goes by many different aliases: wiggle wood, wacky wood, bendy wood, snakewood, meranti, Lauan. Regardless of what you call it, it’s the go-to choice for many fabricators out there. You might say that they’re in an endless ‘luan loop.’

Tom Phillips (no aliases!) has been around the wood industry for more than twenty-five years and spent most of that time in the furniture manufacturing sector. He has worked with nearly every type of wood there is –including luan. He says that fabricators and architects need to understand that while luan is a cost-effective and appropriate choice for some projects, its unpredictable nature can lead to trouble with reliability, quality, and appearance –and that there are alternatives out there that will perform much better.

What Is Luan (or Lauan Plywood? )

First, we need to clear up a little confusion because luan can mean different things to different people.

According to Phillips:

“Luan is a fancy name for something quite simple. It’s basically a piece of plywood with no faces that has been manufactured into sheets”

Luan is sourced mostly from Indonesia or Malaysia. These species of wood that comprise Luan are abundant and each has its own working properties and characteristics – which can lead to headaches for the fabricator.

“The biggest thing you need to accept when working with luan is its unpredictability. If you’re working on a project and you have a lot of time and patience to deal with all the variations, then it may be fine. But for a project with a tight turnaround time or for an installation that has to stand the test of time, I would not choose luan.”

Luan often makes sense for home woodworking projects because it’s only about thirty dollars a sheet from a distributor. But the professionals out there need high-quality materials that deliver consistent results.

“If I were a fabricator, I would worry about how it reflected on me if a customer called me back a few months (in some cases as little as a week) after an installation to fix luan that was warping or curling. It makes you look bad,” says Phillips.

Five Luan Plywood Limitations

Working with luan plywood is a little like a box of chocolates –you never know what you’re going to get.

It’s a commodity product that varies greatly in flexibility, appearance, and thickness and therefore poses these five problems for fabricators and architects alike:

1. Luan Does Not Bend Predictably

The flexibility of luan varies from panel to panel so achieving your bend radius may take extra time and effort. In some cases, luan may not be able to achieve it at all.

2. The Thickness of Luan Sheets Varies

The thickness can vary not only from sheet to sheet but within the sheet itself – sometimes by as much as 1/16″. These variations create headaches for the fabricator, especially when trying to get a consistent look and feel. Varied thicknesses can also cause the panels to break when they’re being bent.

3. Luan Needs A Lot Of Prep Work

The open-pore structure that allows luan to bend and expand can create small gaps that require prep work in order for it to be ready for finishing. You’ll need to sand, patch, and possibly Bondo over the gaps and holes –adding time and expense to your project.

4. Luan Plywood Will Warp Over Time

Because of its unpredictable nature, luan is more prone to warping over time – especially if exposed to extreme conditions or moisture. We’ve seen luan that warped just a few months after installation.

5. The Appearance of Luan Varies From Panel to Panel

This is true of most naturally sourced wood, but if you’re looking for a consistent wood grain appearance, you may want to ditch the luan for an engineered wood product.

One more thing to note:

Luan is never intended to be a final face material. Normally HPL, Veneer, Metal, Paper, or some other thin material must be applied to luan after it has been fabricated with a contact adhesive. This adhesive product is flexible and does not create a reliable glue bond. This process of finishing the luan can be a big labor cost due to the skill required.

Luan Plywood Vs. Kerfkore Products

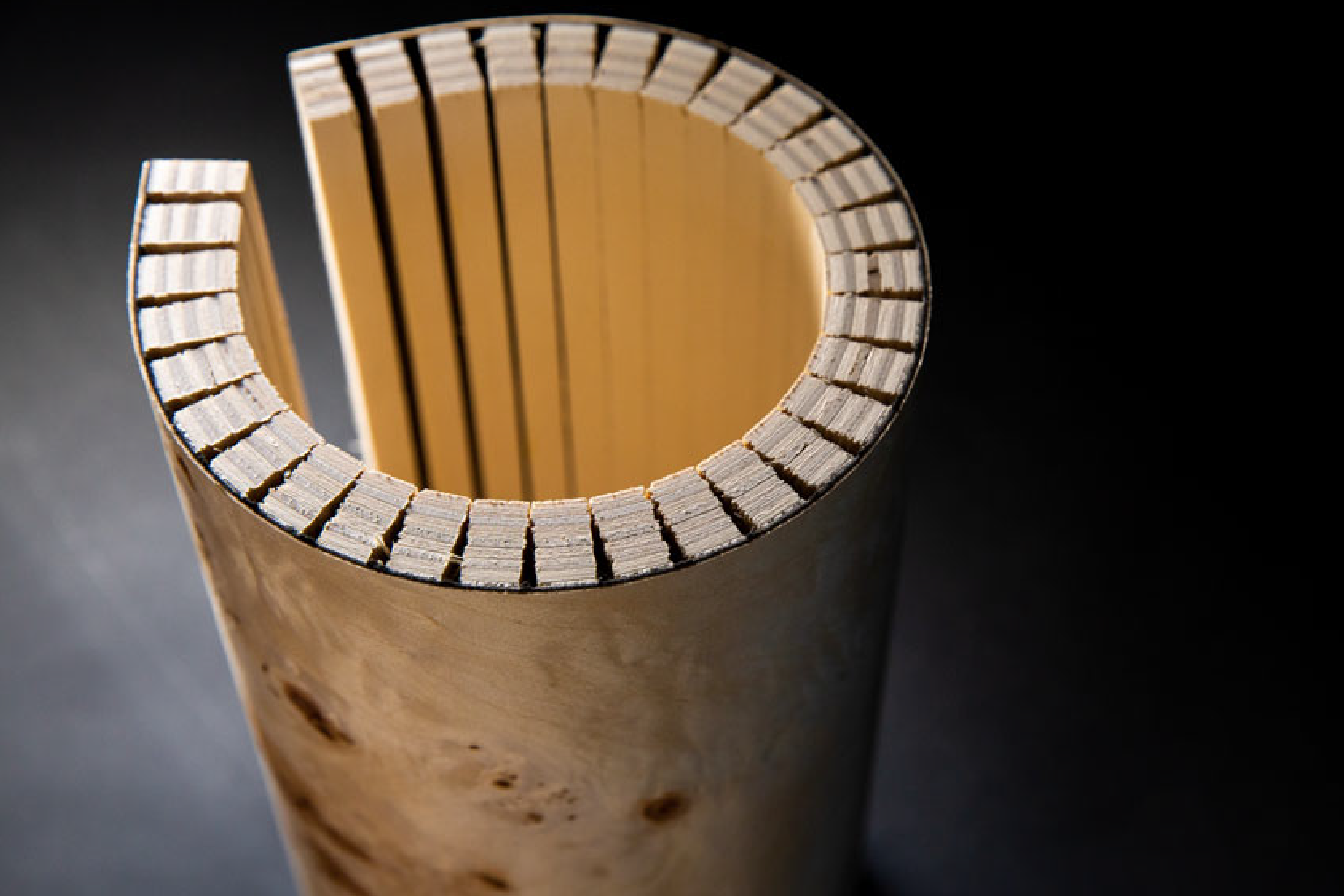

Kerfkore products have many advantages over traditional bendable plywood such as luan.

Kerfkore Products:

- Can bend tighter and with more dimensional stability

- Can be laminated and then curved or curved then laminated depending on your requirements

- Come in a variety of materials, thicknesses, and sheet sizes

- Require little to no sanding, patching, or use of putty/Bondo

- Allow for easier attachment of high-pressure laminates, veneers, metals, leathers, and other semirigid materials for a beautiful finished result.

- Provide superior strength and durability over luan

Phillips advises:

“You’ll be able to install Kerfkore products and walk away knowing that weeks, months, or years from now they’ll still look great.”

Kerfkore’s full line of flexible products includes the original Kerfkore, Timberflex, Econokore, and Flexboard.

It’s Time To Change Up Your Approach

There are subtle differences between how the architect and the fabricator might approach a project, especially if they’ve been in the business for a long time.

“Fabricators tend to think about things from the inside-out. For instance, if they’re given a countertop to create, they will think about the core products and materials first and how to achieve the aesthetic later. Whereas, the architect sees the finished project in their mind first, or outside-in,” says Phillips

Phillips says that working with Kerfkore products helps teams align better because fabricators can now think about the project in the same way architects do.

“When I am educating clients on Kerfkore products, I always stress to the fabricator that you have to look at this differently than the luan. With Kerfkore products you can focus on your finishing products first – the veneer, laminate, etc. – this makes the project go more smoothly.”

In fact, you can attach your finishing products to Kerfkore before you attach them to your framework.

“It’s a little different for fabricators at first, but once they see the advantages – it’s easier to work with and achieve their customers’ vision – they’re sold on it for life. No more luan.”

Your Next Steps:

- Learn more about innovations in bendable wood panels by visiting our Kerfkore product page.

- Get answers to commonly-asked questions by visiting our FAQs page.

- See all of our products, Kerfkore, Timberflex, Econokore, Worklite, and Flexboard in-situ by visiting our gallery page.

- Check out our recent article 9 Questions To Ask Your Curved Wood Panel Supplier.

- Subscribe to our blog for wood industry news delivered right to your inbox.