Flexboard Case Study: Texas A&M-Kingsville Music Education Complex

December 13, 2023At Kerfkore, we’re proud to have our products utilized in a variety of stunning settings, from fine-dining interiors to Slam Grand Pianos. In our latest case study, you’ll witness Kerfkore in a higher education environment and discover how Flexboard helped streamline a university’s brand-new music education facility at Texas A&M-Kingsville, meeting density and flexibility specifications, enhancing both acoustics and aesthetics and significantly cutting costs.

THE CUSTOMER

Brochsteins, based in Houston, Texas, fabricates custom architectural millwork and furniture for Fortune 1000, law firm, hospitality, museum, and higher education clients.

For almost 90 years, both architects and general contractors have relied on Brochsteins to bring their design vision to life with unique pieces and extraordinary spaces.

Photo by Cotton Global Disaster Solutions.

THE OPPORTUNITY

Brochsteins was approached by Texas A&M University-Kingsville in regards to building the Music Education Complex. The new Complex would replace the aging Bellamah Music Building, which was now too small for a program that had grown significantly over the past 60 years. This project was set to triple the music program’s space from 32,000 square feet to 90,000 square feet including a stunning, 500-person performance hall to visually enhance and provide a tangible demonstration of the department’s contribution to the larger campus.

The fabricators at Brochsteins had worked with Kerfkore products in previous projects, and knew it was the optimum solution to provide both the flexibility and density required for the wraparound balcony with varying heights.

Photo by Cotton Global Disaster Solutions.

THE SOLUTION

Since Brochsteins had previously utilized Kerfkore products, they were quick to recommend Flexboard® to complete the auditorium’s ornate balcony wrapper instead of a more cost-prohibitive design of wood strip lamination. By moving to a panel system centered around Kerfkore’s Flexboard® panels, the team was able to condense the amount of field time required, lowering both labor costs and the timeline to project completion.

More than 73% in cost savings for overall project budget

The construction of the balcony wrapper was also a complicated endeavor, with various height changes ranging anywhere from four feet tall in the front to fifteen feet tall in the back. Due to the slope of the design, there were several areas that required cutting and refilling to ensure the panels were seamless and smooth throughout. Kerfkore’s Flexboard® panels met this challenge head-on, and Brochsteins was able to uniquely treat all the vertical reveals to hide any exposed edges.

Brochsteins opted to finish the Flexboard® panels with a Mozambique wood veneer, a finish that is in high demand for upscale architectural designs.

This wood has a rich appearance, full of classic character and natural luster. The stronger and more intense the dark veining that runs up and down the veneer, the more valuable the wood becomes.

This type of wood is also often the optimum choice for constructing musical instruments, so it’s in good company within its new home, calling the eye upwards, warming the space, and working well to enhance the other wooden finishes throughout.

Flexboard panels offered the most efficient and effective solution.

When comparing the Flexboard panels to other alternatives, like bending plywood, to achieve this panel system design, Flexboard was found to be the most efficient solution.

If the alternative option, bending plywood, had been used in its place, it would have been a more laborious endeavor for all involved, requiring an individual template for each module and a vacuum-pressed lamination of the specific shape.

Even with this laborious option, it would be a significant challenge to get to the density requirement of the project, as the number of sheets required to be layered to reach that required density thickness would have increased both the material and labor costs.

Additionally, the balcony wrapper’s slope, which complicated the project further, would have required individual templating per module, adding to the project’s delivery timelines.

The performance hall also had several acoustical and density requirements that required special consideration. By double layering the Flexboard panels, they were able to meet the density specifications and sound reflective requirements.

The panels’ hard surfaces are essential in delivering full, robust sound throughout, and were paired with strategically placed soft surfaces to keep both reverberations and echoes under control. With the balcony panels’ ability to scatter sound and enhance reverberance while still creating an eye-catching design, Flexboard was able to help create an immersive atmosphere for all audience members seated throughout the 500-person hall.

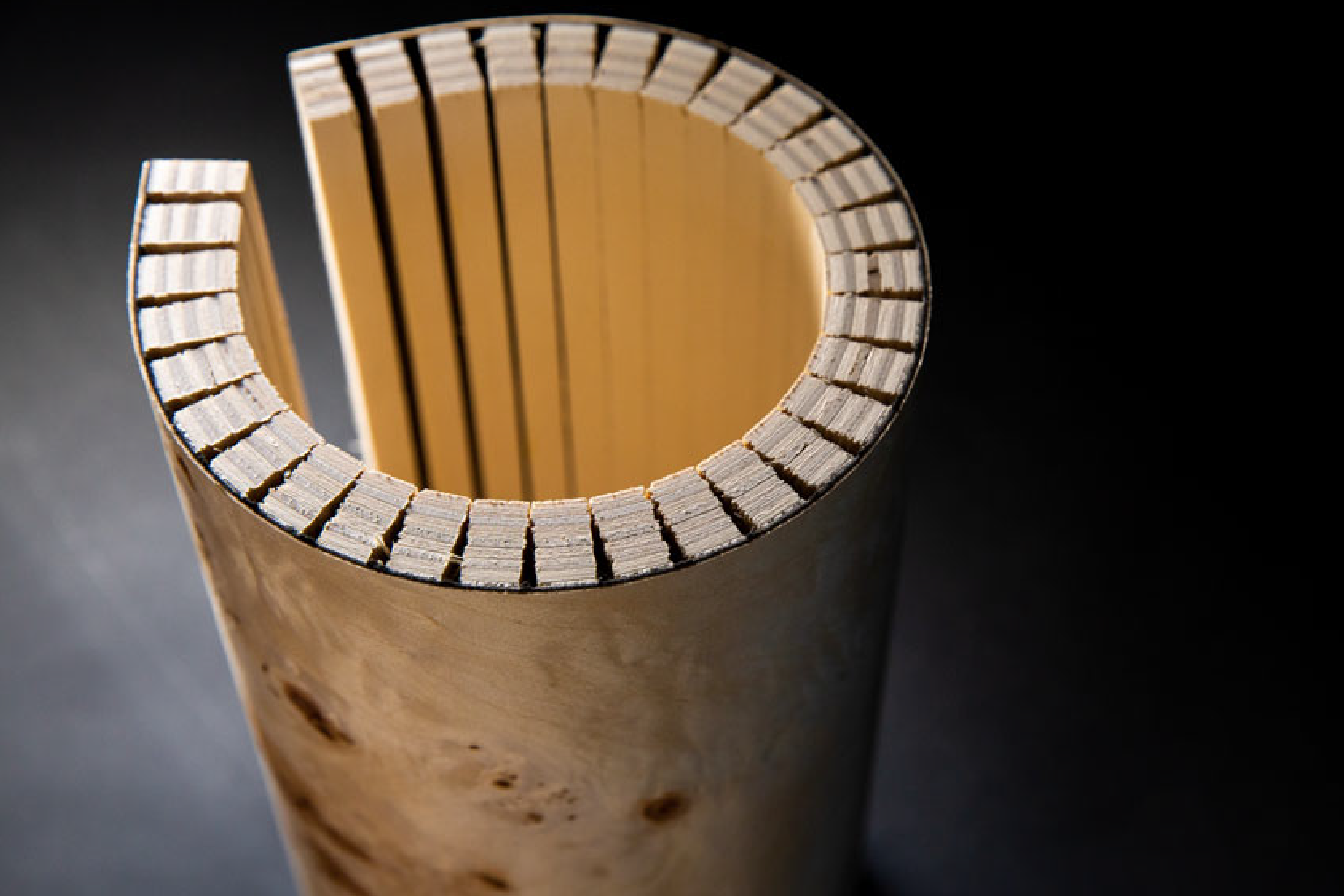

THE PRODUCT

Flexboard flexible panels integrate Kerfkore’s unique base layer manufacturing process with a 0.090” Eucalyptus hardboard face that creates a flexible yet extremely stable base layer for a variety of uses. It was able to work within the confines of the design’s slope that ranged from four feet tall in the front sections of the hall, and wrapping around in growing lengths until it reached its pinnacle at fifteen feet in the rear

KEY BENEFITS:

- Smooth Eucalyptus Hardboard Face

- Flexible base layer with a maximum 8″ bending radius

- Doubling up panels met density requirements

- Able to easily fit varying height requirements

- Can be finished with a variety of veneers, high-pressure laminates, metals, and more

It is available in multiple sizes with a variety of core materials, making it the perfect solution for a range of projects.

Photo by Cotton Global Disaster Solutions.

THE RESULTS

For the design team, leveraging Kerfkore panels to complete the balcony wrapper portion of this project offered tremendous benefits. For one, these flexible panels eliminated both the costly materials and extra labor installation required, helping to keep the project under budget and within the preferred timeline.

Additionally, Flexboard® panels were able to easily meet the specified density requirements for the project by simply double-layering the panels throughout.

In the end, Kerfkore’s flexible panels were essential to ensuring a fluid aesthetic for the wrapping, despite the varying heights and wave-like flow. Unlike other resource-intensive products that would require templating and vacuum-pressed lamination efforts, Flexboard® panels were able to alleviate any unnecessary stress and pressure in order to complete the project.

Despite the challenging nature of this project, Kerfkore was the correct solution to meet each of the project specifications and needs.

Since opening in 2021, the performance hall has been a cornerstone for a variety of events held on the Kingsville campus.

In the future, Brochsteins intends to continue using Kerfkore products in a variety of projects that need the flexibility and level of customization that these panels offer.

Download the PDF version of the case study here.

Put Flexboard in Your Next Project

Discover how the flexible Flexboard can give your next project dynamic aesthetics while remaining cost-effective when you request a free sample today.

All Photos by Cotton Global Disaster Solutions.