Why Kerfed Wood Should be Your Choice for Flexible Architectural Panels

February 6, 2023

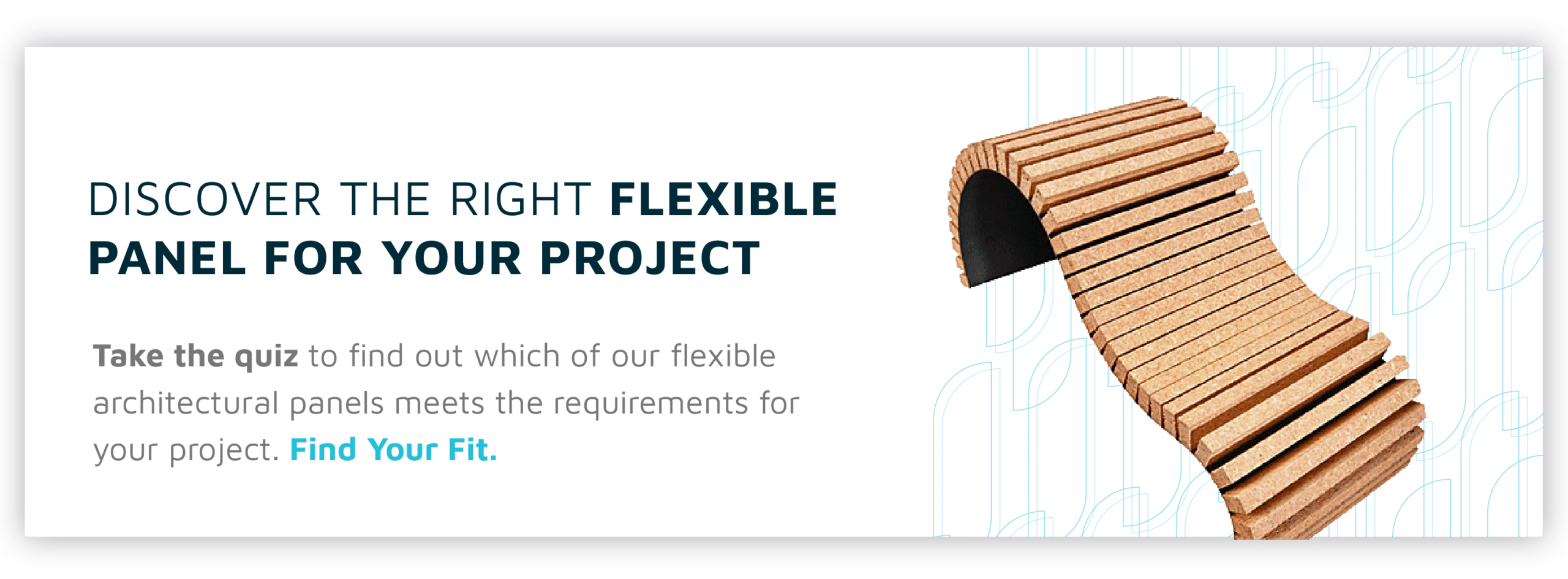

Kerfed wood panels are redefining what’s possible in architectural design. From smooth curves and arches to complex S forms, kerf cutting allows wood to bend without sacrificing strength, precision, or aesthetics.

What is Kerfed Wood?

Ever wonder where we got our company name from? Kerfkore is based on the word kerf, which is a technique in woodworking used to create bends and curves.

For many, woodworking is associated with straight and traditional designs. But with kerfing, we can create elegant, dynamic, and modern woodworking that defies expectations.

Kerfed wood is created using kerf cuts, where a series of closely spaced cuts are made into the back of a wood panel. A kerf cut refers to the slot or channel left behind when material is removed by a cutting tool, traditionally a saw blade.

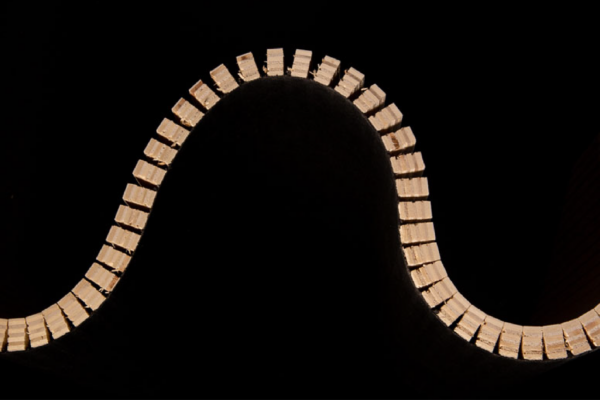

These cuts reduce material resistance, allowing the panel to bend smoothly along a controlled radius, similar to how a bendable straw flexes at its grooves.

When kerf cuts are applied consistently and precisely, rigid wood becomes flexible enough to form curves, arches, and organic shapes.

The History of Kerf Cutting in Woodworking

It’s tough to tell exactly where and when the kerf cut was invented. Woodworking is one of humanity’s oldest industries, and the kerf-cutting technique, by all records, seems like it’s been around for a while. According to the Oxford English Dictionary, the earliest known use of kerf dates back to the Old English period.

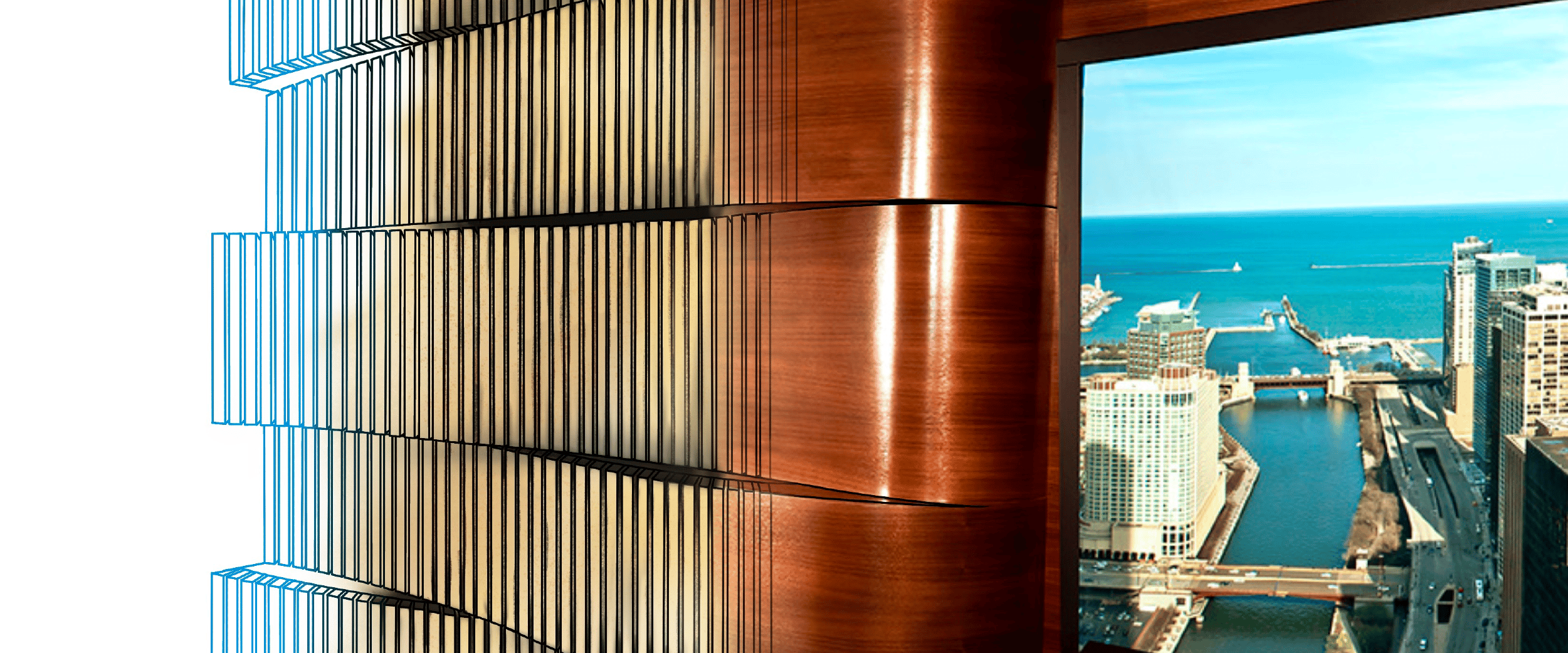

While the technique is ancient, its modern applications are anything by traditional. Today, kerfed wood panels are used to create bold architectural features that would be impossible to achieve with standard flat materials.

Why Choose Kerfed Wood for Architectural Panels?

Kerfed wood combines design freedom, structural consistency, and material reliability, making it ideal for modern architectural applications.

While it’s an age-old technique, it can be used to create incredibly modern shapes. The elegant curves of wooden instruments like grand pianos and acoustic guitars can be executed with kerf bending, as well as archways, curved ceiling baffles, and a plethora of other eye-catching architectural designs.

The possibilities are endless. The psychological benefits of arches and curves have been well-documented. There is something natural and welcoming about curves, which kerfing allows us to achieve with wood because it creates stability and consistency.

Key Benefits of Kerfed Wood Panels:

- Smooth, continuous curves

- Consistent bending radius across multiple panels

- Greater durability compared to alternatives, like plywood

- Precision engineering for professional-grade installs

- Natural warmth and visual appeal of real wood

- Ease of attaching veneers and high-pressure laminates

Kerfed Wood vs. Bendable Plywood (Bending Luan)

Bending plywood, also known as bending luan or wacky wood, can be used as an alternative, but it often comes with trade-offs.

Limitations of Bendable Plywood:

- Inconsistent quality from sheet to sheet

- Unpredictable bending radius

- Higher risk of breakage

- Increased material waste and project delays.

While bending luan may be inexpensive upfront, failed panels and trial-and-error fabrication often increase total costs.

By contrast, engineered kerfed wood panels deliver predictable performance and consistent results, especially for complex designs like tight curves or S-curves, where bendable plywood struggles.

Real-World Applications of Kerfed Wood Panels

Kerfed wood panels are used across a wide range of commercial and architectural environments, including:

- Reception desks

- Museum displays

- Trade show booths

- Retail displays

- Retail interiors and displays

- Pre-fabricated and mobile homes

- RVs and camper vans

- Restaurant booths

Any project that calls for curved surfaces with a refined finish can benefit from kerfed wood.

Self-Kerfing vs. Pre-Engineered: What’s the Difference?

DIY kerfing can work for small-scale projects, but it becomes increasingly time-consuming and risky as complexity increases.

Challenges of Self-Kerfing:

- Labor-intensive cutting process

- Risk of uneven cuts and telegraphing

- Wasted materials due to mistakes

- Bending limits or inconsistency

Advantages of Pre-Engineered Kerfed Wood:

- Eliminate the guesswork of the bending radius

- Consistent bending across the project

- Focus on execution rather than setup

- Save time, labor, and material costs

Frequently Asked Questions About Kerfed Wood Panels

How can I finish kerfed wood panels?

It depends on the facing of your kerfed wood panel! At Kerfkore, all of our panels can be finished with a high-pressure laminate or veneer. Timberflex can be painted or stained, and our Flexboard and Econokore panels can be painted.

What is the tightest bending radius kerfed wood panels can achieve?

Depending on the panel you choose, the tightest bending radii that Kerfkore panels can achieve range from 3.5” to 12”.

Why should I use pre-fabricated kerfed wood panels over bendable plywood?

Bendable plywood is not always reliable. The quality can vary board to board, resulting in broken panels and trial-and-error. A pre-fabricated kerfed wood panel from Kerfkore provides consistent, dependable results every time.

See the Quality of Kerfkore in Action

Kerfing is a timeless technique. One that we think we’ve honed into a combination of art and science to deliver some of the most aesthetically pleasing architectural panels a designer or fabricator could hope for. Request a sample of Kerfkore and experience the high-quality pre-engineered kerfed wood for yourself.