What Makes a Smart Architectural Panel? A Look at Kerfkore’s Panel Construction

February 5, 2026In architecture, “it looks great” only matters if it actually works. Architects, designers, and fabricators rely on panels to do more than just look good. Panels must perform—consistently, predictably, and efficiently—across design intent, fabrication, and installation. Yet traditional panel materials often introduce challenges that slow projects down, increase risk, and compromise results. From inconsistent bending to excessive weight and labor-intensive processes, conventional solutions can work against even the most thoughtful designs.

That’s where smart architectural panels come in.

What Does “Smart” Mean in Architectural Panel Construction?

In this context, a smart panel isn’t about technology; it’s about engineering. Smart architectural panels are built with intention, using high-quality materials and engineered construction to deliver predictable performance every time. They’re reliable across production runs, efficient to fabricate and install, and designed to reduce risk rather than introduce it.

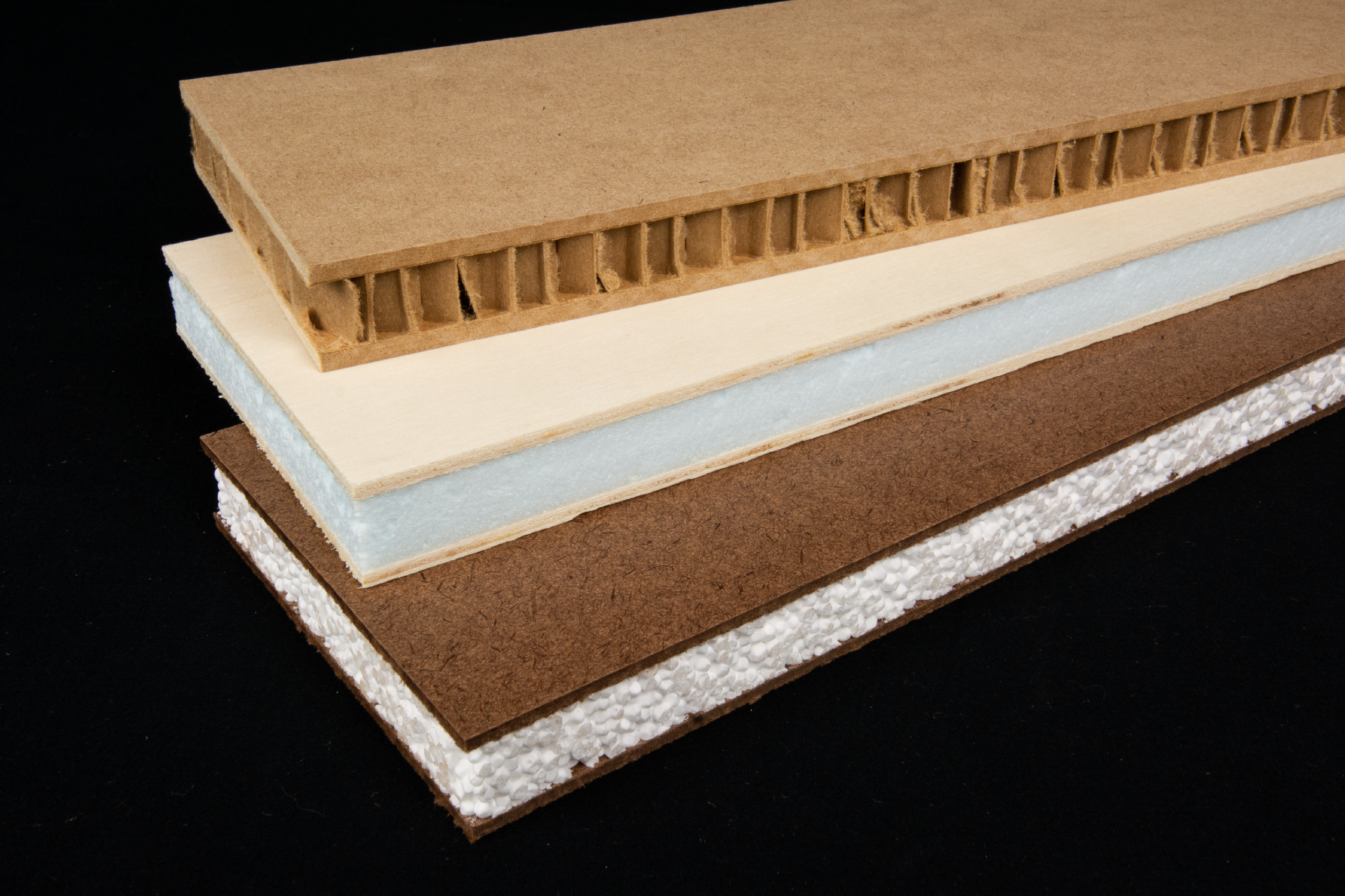

At Kerfkore, smart panel construction comes down to two core advantages: flexibility and lightweight strength. Both are made possible by what’s happening beneath the surface—at the core.

Kerfkore’s Approach to Smart Architectural Panel Construction

Kerfkore panels are built differently by design. Kerfkore uses engineered cores developed specifically for architectural applications.

This engineered approach delivers consistency, repeatability, and performance that traditional materials simply can’t match. Because the core is designed, it directly controls key performance factors such as bend radius, panel weight, structural integrity, and fabrication time.

In short, the core determines how a panel behaves. And smart panels start there.

Flexible Panels: Smart Construction for Curves Without Compromise

The Problem With Traditional Materials

Creating curved forms with traditional panel materials has always been a challenge. Plywood, MDF, and hand- or CNC-kerfed panels come with inherent limitations:

- Inconsistent bending from panel to panel

- Cracking, telegraphing, and surface distortion

- Structural weakness at kerf cuts

- Labor-intensive fabrication and setup

These methods rely heavily on manual processes and variable material properties, which increases the likelihood of failure—especially on tight radii or complex curves.

Kerfkore’s Flexible Panel Construction

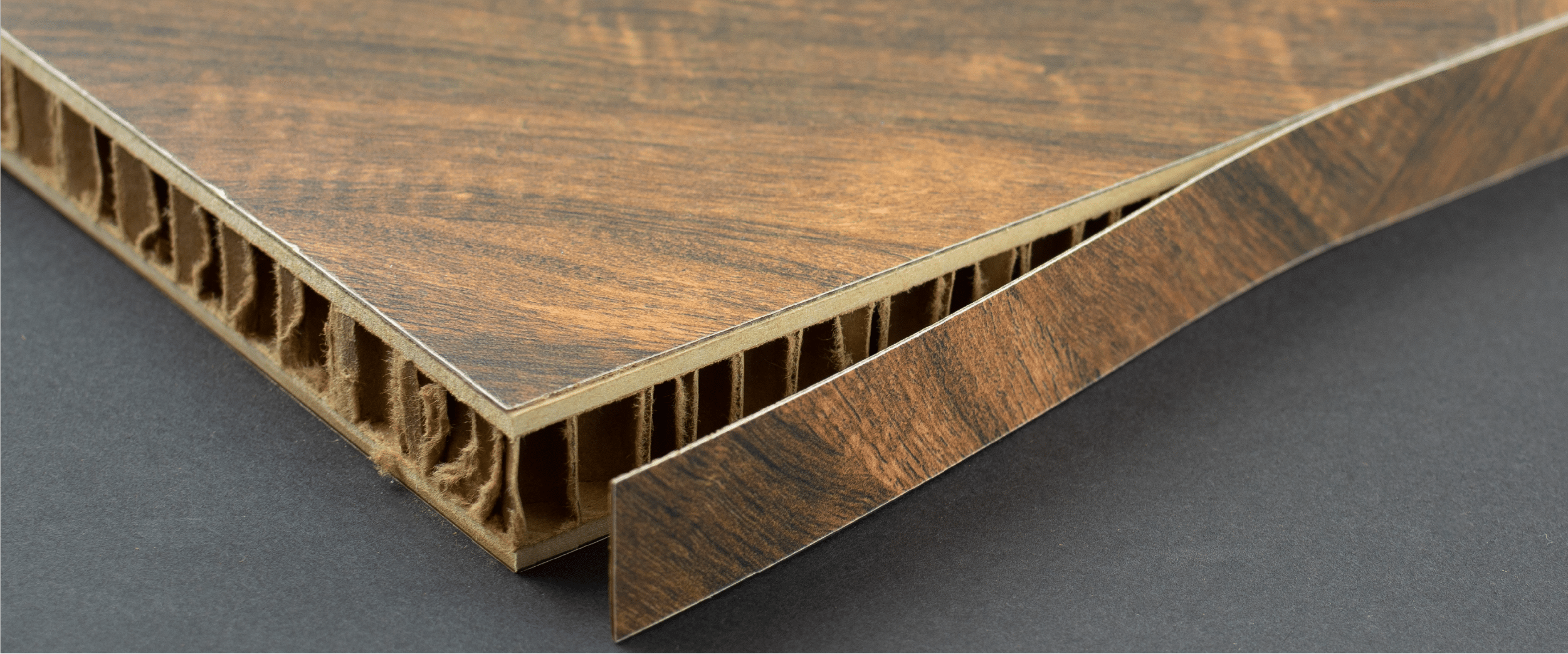

Kerfkore solves these problems by engineering flexibility directly into the panel core. Instead of cutting kerfs after the fact, Kerfkore builds precise, controlled kerf patterns into the core during manufacturing.

The result is consistent flexibility across the entire panel, with predictable bending and minimal spring-back. Panels flex smoothly while maintaining structural integrity, making it easier to achieve clean, repeatable curves without surface compromise.

Kerfkore Flexible Panel Options

Kerfkore offers a range of flexible panel solutions to suit different applications and performance needs, including:

Each option is engineered for reliable bending while supporting a wide variety of laminates, veneers, and finishes.

Why Flexible Panels Save Time and Reduce Risk

Because flexibility is engineered into the core, Kerfkore flexible panels dramatically reduce fabrication time and installation risk. Shops spend less time kerfing, fewer panels fail during forming or installation, and finished surfaces remain smooth and clean—especially important for decorative laminates, veneers, and solid surfaces.

Worklite Lightweight Panels: Smart Construction That Reduces Weight Without Sacrificing Performance

The Challenges of Heavy Traditional Panels

Weight is another major pain point with traditional panels. Heavy materials make handling difficult, increase shipping costs, and slow down installation. They can also add unnecessary structural load, forcing designers to over-engineer supporting systems.

How Kerfkore Worklite Panels Are Made

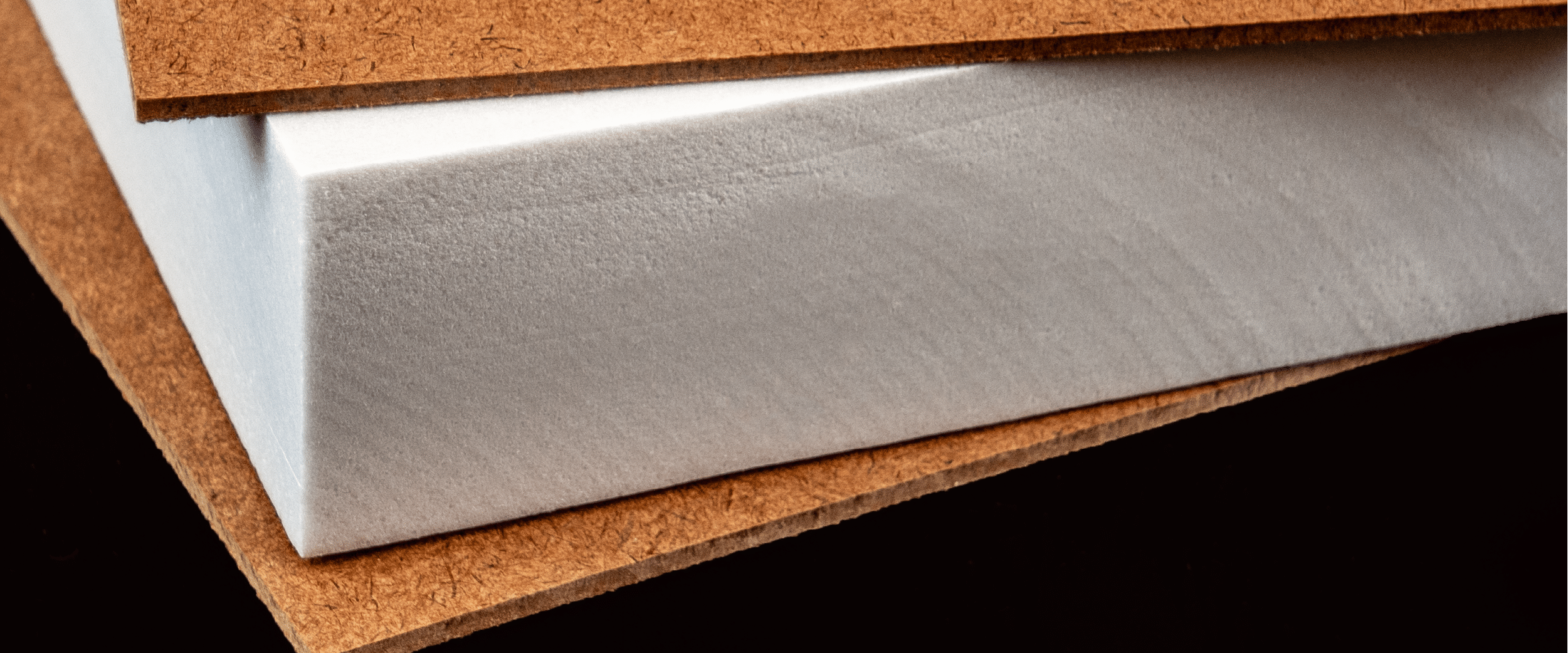

Kerfkore lightweight panels use foam core technology paired with rigid faces to achieve optimal strength-to-weight performance. These engineered cores are designed for dimensional stability and flatness, ensuring panels stay true over time.

Despite their reduced weight, Kerfkore lightweight panels are built to support laminates, veneers, and a wide range of architectural finishes—without compromising durability or performance.

Kerfkore Worklite Options

Kerfkore’s lightweight solutions include:

Each option is engineered to balance weight reduction with structural reliability, making them ideal for both vertical and horizontal applications.

Benefits of Lightweight Panels

Lightweight construction delivers tangible benefits throughout a project:

- Easier handling and faster installation

- Reduced structural load

- Lower shipping and labor costs

For fabricators and installers alike, lighter panels mean smoother workflows and fewer headaches.

Smart Panel Construction Starts at the Core

Architectural panels don’t perform by accident. Their success depends on thoughtful construction—starting at the core. By engineering flexibility and lightweight strength directly into its panels, Kerfkore eliminates the unpredictability of traditional materials and replaces it with consistency, efficiency, and confidence.

Kerfkore panels don’t just look good—they’re built smarter.

Ready to experience the difference? Explore Kerfkore’s full line of architectural panels or request a sample kit to see—and feel—the construction firsthand.