Beyond the Straight-Edge: How Soflex Tackles Office Furniture Pain Points

June 18, 2025Turning curved concepts into commercial reality—without the cost, weight, or wait.

The Office Furniture Challenge

Office furniture makers are being squeezed from all sides:

Meet Soflex: The Flexible Panel Built for Modern Workplaces

Soflex is Kerfkore’s ultra-flexible substrate that bends to a 3 ½-inch inside radius without losing structural integrity, thanks to its proprietary LTX backer. Products can be laminated first then formed into a wave, arch, cylinder or S-curve—no steam boxes, no kerf saw blades, and no telegraphing.

Why it excels in contract furniture

- Laminate-then-form workflow – Apply high-pressure laminate, metal, or veneer while the sheet is still flat, slashing touch time and boosting repeatability.

- Easy-Splice™ – Edge-glue off-cuts together under the laminate, turning scrap into value-adding surface area.

- Weight and framework reduction—Curves lock in place without heavy ribs, so reception desks or acoustic baffles stay lighter and cheaper to ship.

- Scalable creativity – One SKU in the stockroom can morph into multiple radii, letting dealers customize fast-track orders without extra inventory.

Solving the Five Big Pain Points—One Curve at a Time

| Pain Point Solved | Soflex Advantage | Office Furniture Wins |

| Lead-time pressure | Eliminates cuts left by tools & steam processes. Laminate flat for a fast, consistent process. | Quick-turn panels keep build outs on schedule. |

| Labour scarcity | Anyone who can laminate plywood can work with Soflex—no specialized training needed. | Shops redeploy skilled carpenters to high-margin finishing work. |

| Material waste | Easy-Splice re-uses trim pieces, and the precise bending radius avoids trial-and-error. | Helping clients hit zero-waste targets. |

| Weight & shipping cost | Lighter core means more units per pallet and simpler in-field installs. | Facilities teams install curved reception counters directly on the floor without renting heavy equipment. |

| Demand for adaptable aesthetics | Single panel flexes into multiple curves. Surfaces accept HPLs to match corporate palettes. | Designers refresh lounge zones with organic forms that reinforce brand identity. |

Soflex Application Playbook for Office Settings

- Reception & Concierge Desks – Signature wave fronts that still allow wiring chases and ADA knee-spaces.

- Privacy Pods – Tight 3.5″ radius lets you build rounded corners that boost acoustics without extra framing.

- Hot-Desking Benches – Kidney-shaped or serpentine benches encourage collaboration while preserving leg room.

- Break-Room Banquettes – Curved upholstery substrates bend on site, perfect for tight elevator cores.

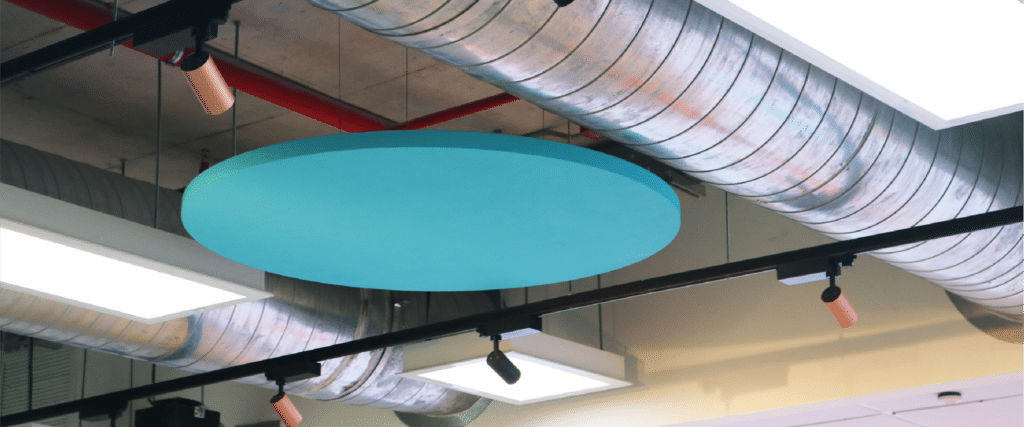

- Acoustic Baffles & Ceiling Clouds – Lightweight panels hang easily, diffusing noise in open-plan floors.

Future-Proofing the Furniture Line

Market analysts predict continued pressure on raw-material availability and shorter project cycles through 2026. Manufacturers embracing flexible substrates and additive processes (e.g., 3D printing for jigs) are positioning themselves to out-run disruption.

Soflex aligns neatly with this shift—combining design freedom, supply-chain resilience, and lean production into one SKU. For contract-furniture brands, that means lower total cost of ownership and a product story specifiers can rally behind.

Ready to Bend the Rules?

Experience the Soflex difference in real numbers and real time: shops report up to a 30% cut in labor hours versus manual bending and 15–20% material savings when easy-splice—a technique that joins boards end-to-end without extensive cutting or intricate shaping—replaces cumbersome plywood sub-structures.

If your next office furniture build demands curves that command attention—without stretching budgets or schedules—bend the rules with Soflex. Request a sample, and see how effortlessly it transforms flat sheets into statement-making curves. That’s the Soflex difference.