WORKLITE XPS FOAMKORE

WORKLITE XPS FOAMKORE Overview

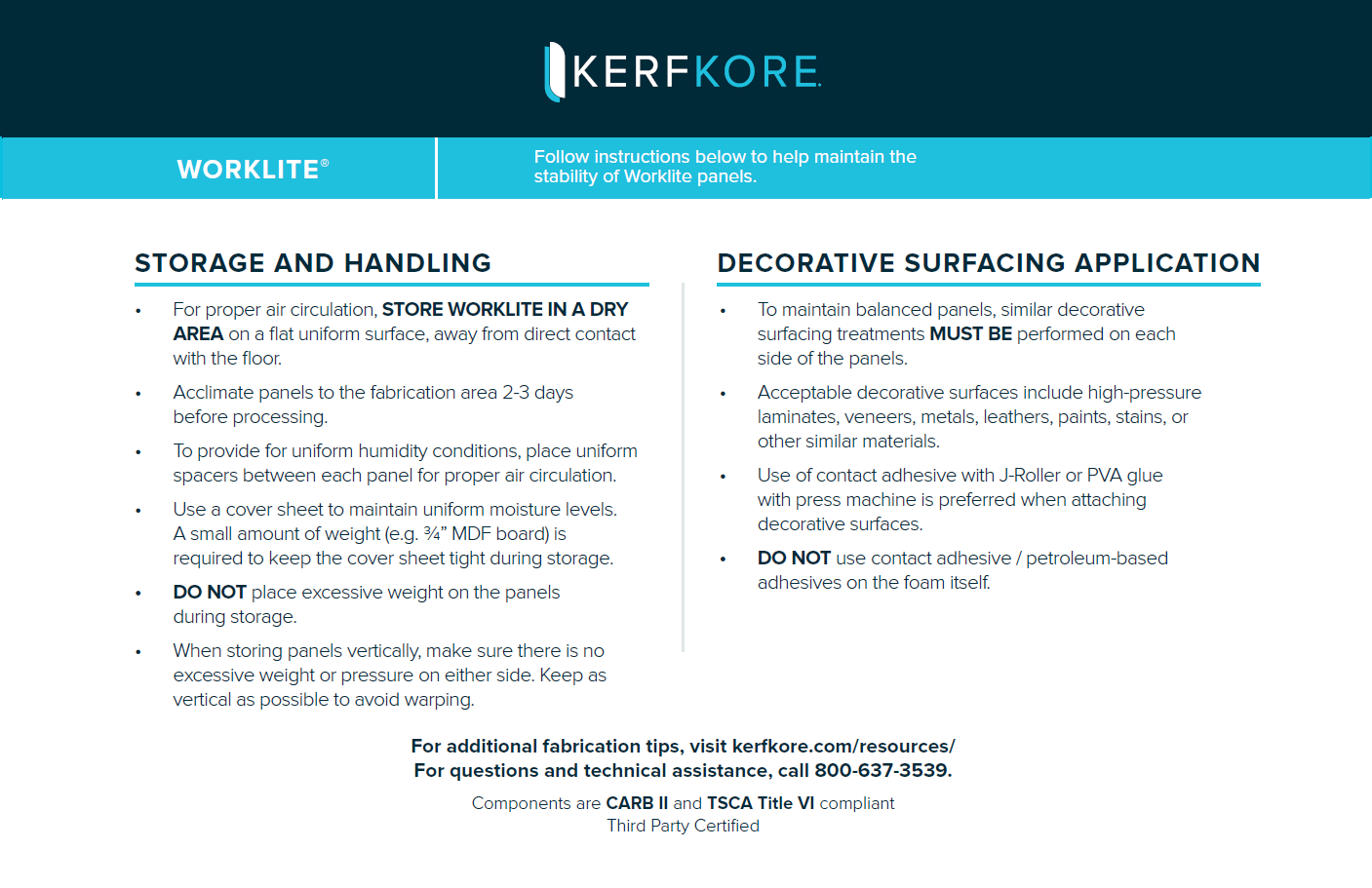

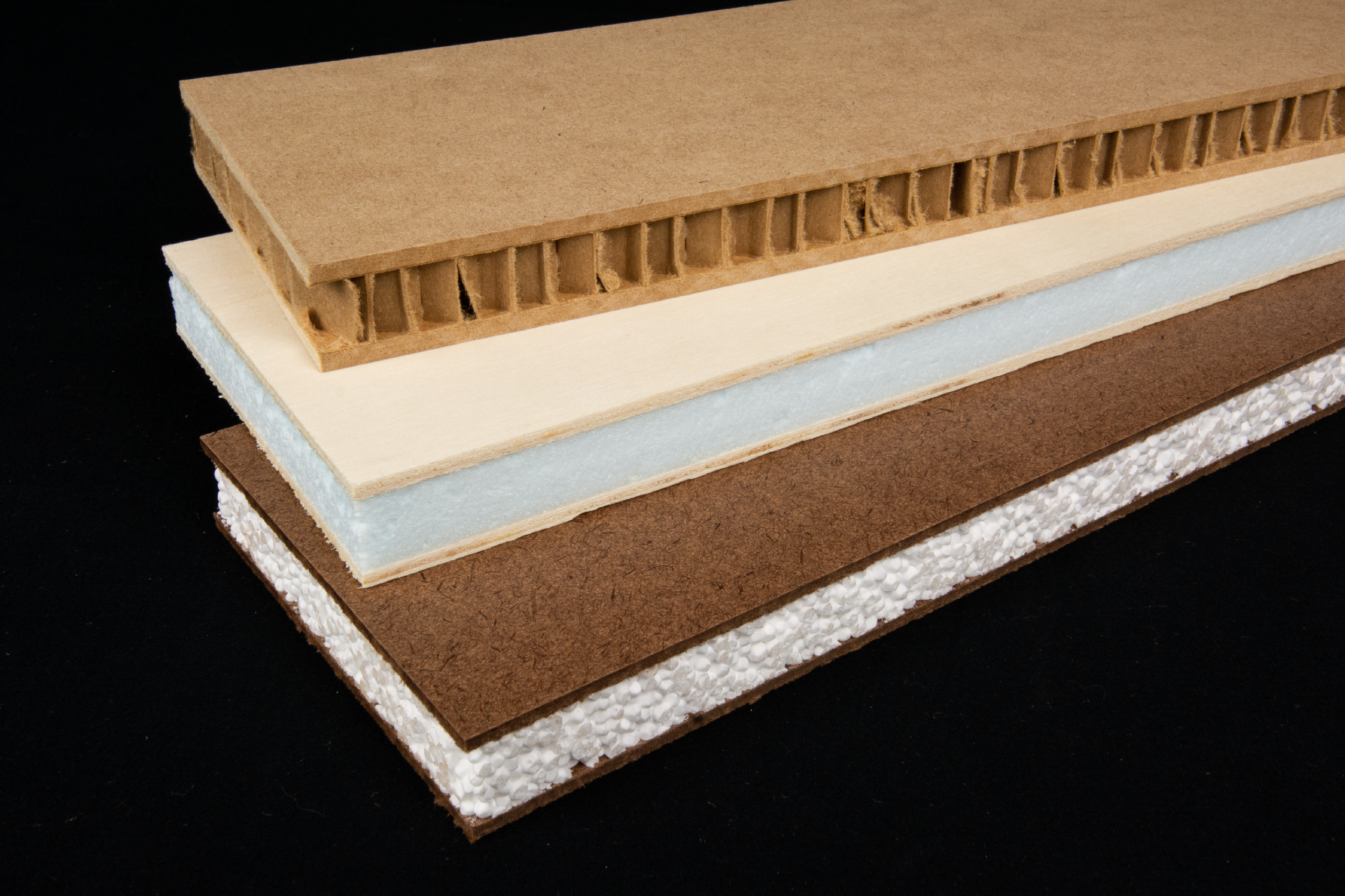

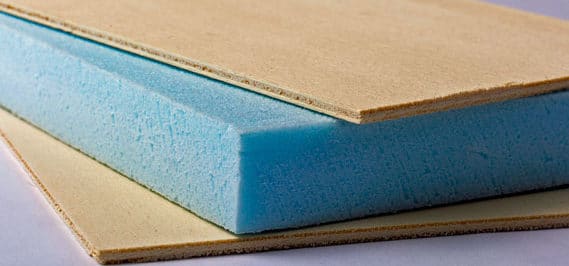

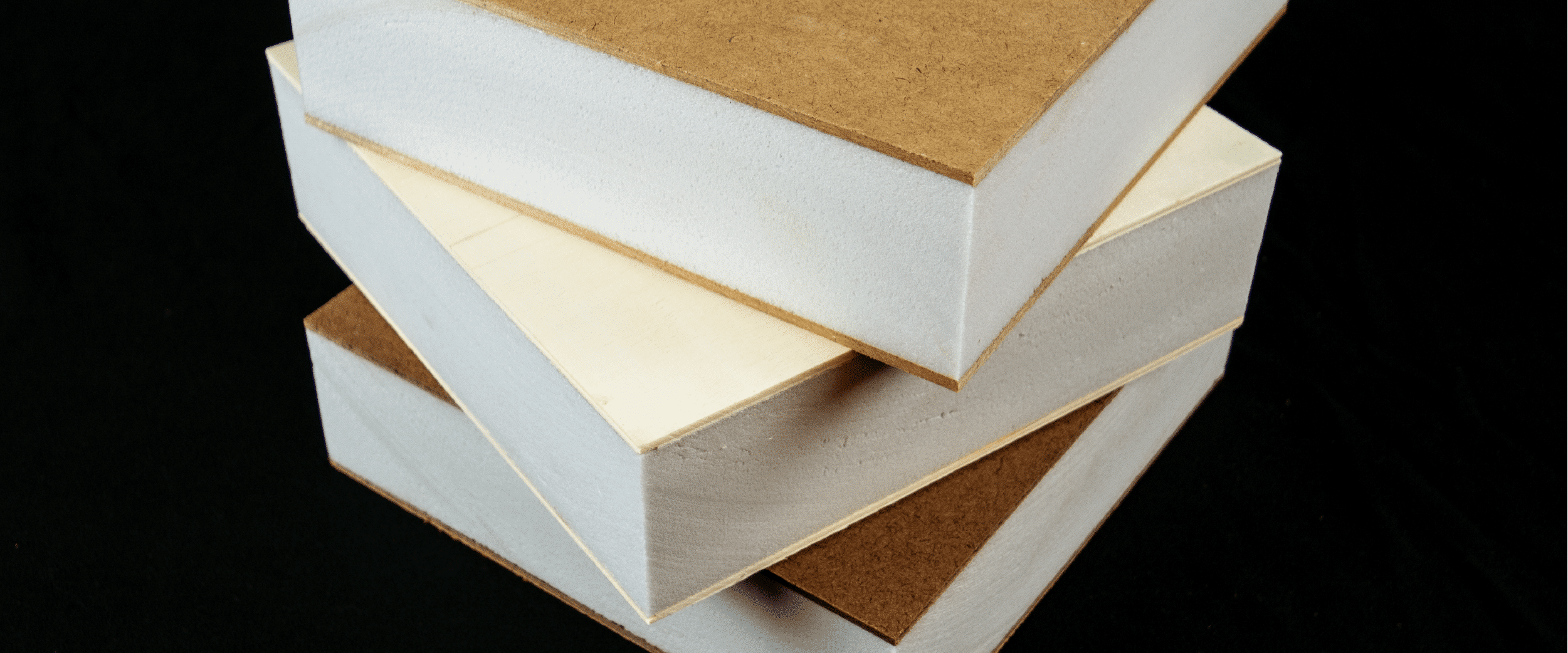

Our Worklite XPS Foamkore lightweight panel reduces material weight up to 80%* by capturing a lightweight core between two thin high-density faces, resulting in a strong lightweight panel with structural integrity. Core material is a dense closed-cell Styrofoam that provides moisture resistance, thermal performance and compressive strength. Some panels can weigh as little as 12 oz/sf while still providing a 1/8″ plywood faced panel to achieve a 3/4″ overall thickness. Panels can be covered with high-pressure laminates, veneers, metals and many other semirigid materials as well as stained or painted.

*Compared to conventional panels made of plywood, particleboard and MDF

WORKLITE XPS FOAMKORE BENEFITS

80% Weight Reduction

In combination with rigid faces and 2lb density polystyrene, the XPS panel provides a high strength to weight ratio *Compared to plywood, particleboard, and MDF

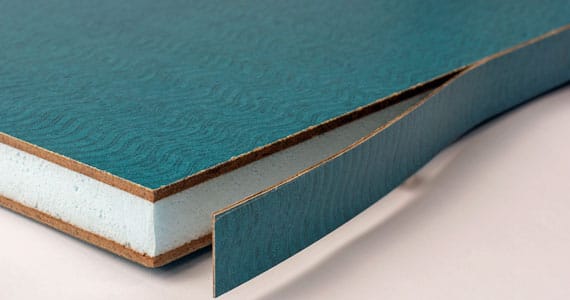

Smooth Panel Edges

Our XPS process provides a tighter polystyrene alignment, creating smooth and consistent edges that are paint ready

Edge Band Ready

Variety of edging options such as edge insert, outer edge band and conventional edge banding

TECHNICAL OVERVIEW

Face Materials

Eucalyptus Hardboard (Standard)Fiberboard

3-Ply Italian Poplar Plywood

Core Materials

Extruded Polystyrene (Standard)

WORKLITE XPS FOAMKORE FAQS

How do I use Worklite XPS Foamkore?

Our Worklite XPS Foamkore lightweight panel can be installed using conventional fabrication methods.

- Size XPS Foamkore to the desired finished dimensions.

- Apply the decorative surfacing material using a water or solvent based contact adhesive or a standard PVA glue (not a cross linking type).

- Allow glue to fully dry according manufacturers recommendations.

- Use a router to easily trim the decorative surfacing material to match the finished size.

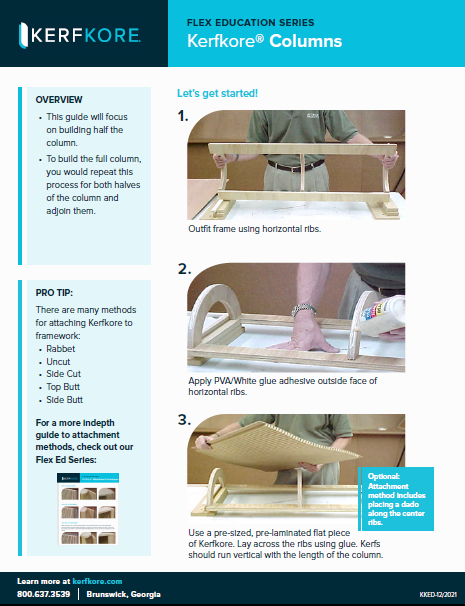

How do I attach Worklite XPS Foamkore to a framework?

The Worklite XPS Foamkore rigid face materials provide the ability to use conventional methods of attachment. The use of glue, staples, nails, screws, and other similar fasteners will allow the panel to be physically and structurally attached to other materials.What decorative surfacing material can I use on Worklite XPS Foamkore?

Almost any decorative surfacing material can be used. Options Include:

- HPL

- Phenolic backed veneer

- Two-ply veneer

- Three-ply veneer

- Paperbacked veneer

- Metal

- Many other semirigid materials

- Face material can also be painted

How do I edge band Worklite XPS Foamkore?

There are a few ways to handle this.

- An edgebander can be used, it’s recommended to use a 2mm or 3mm thickness as this will give the impact resistance needed due to the heat and solvent based glue slightly melting the foam. The edgebanding will adhere to the face materials. Kerfkore Company can provide internal perimeter framing.

- If it is necessary to use an edgebander with traditional edgeband thicknesses, remove or route out the foam edges and glue in a solid wooden edge.

- A third edgebanding option is to use a water based adhesive and apply edge banding by hand.

PRODUCT TESTIMONIAL

"In using Kerfkore products, I find it has saved me in time and labor over traditional methods. It gives me a consistent result every time. It also has expanded our ability to be creative for the customer."Roger Smith | Third Day Creations