Bending the Rules: How Kerfkore Soflex is Shaping the Future of Furniture Manufacturing

May 5, 2025Let’s be honest—working with traditional furniture materials can make designing curves feel like more of a hassle than a highlight. Stiff boards, tedious kerf-cutting, and too much time spent wrestling with tools can drain the fun out of a great idea.

That’s where Kerfkore’s Soflex comes in. This flexible substrate is changing the game for designers and manufacturers. Whether you’re bringing a bold, curvy concept to life or just trying to streamline your production process, Soflex helps you shape smarter—not harder.

In this blog, we’ll take a closer look at why Soflex is a go-to solution and how it’s helping fabricators create standout designs faster, cleaner, and with a lot less friction.

What is Soflex?

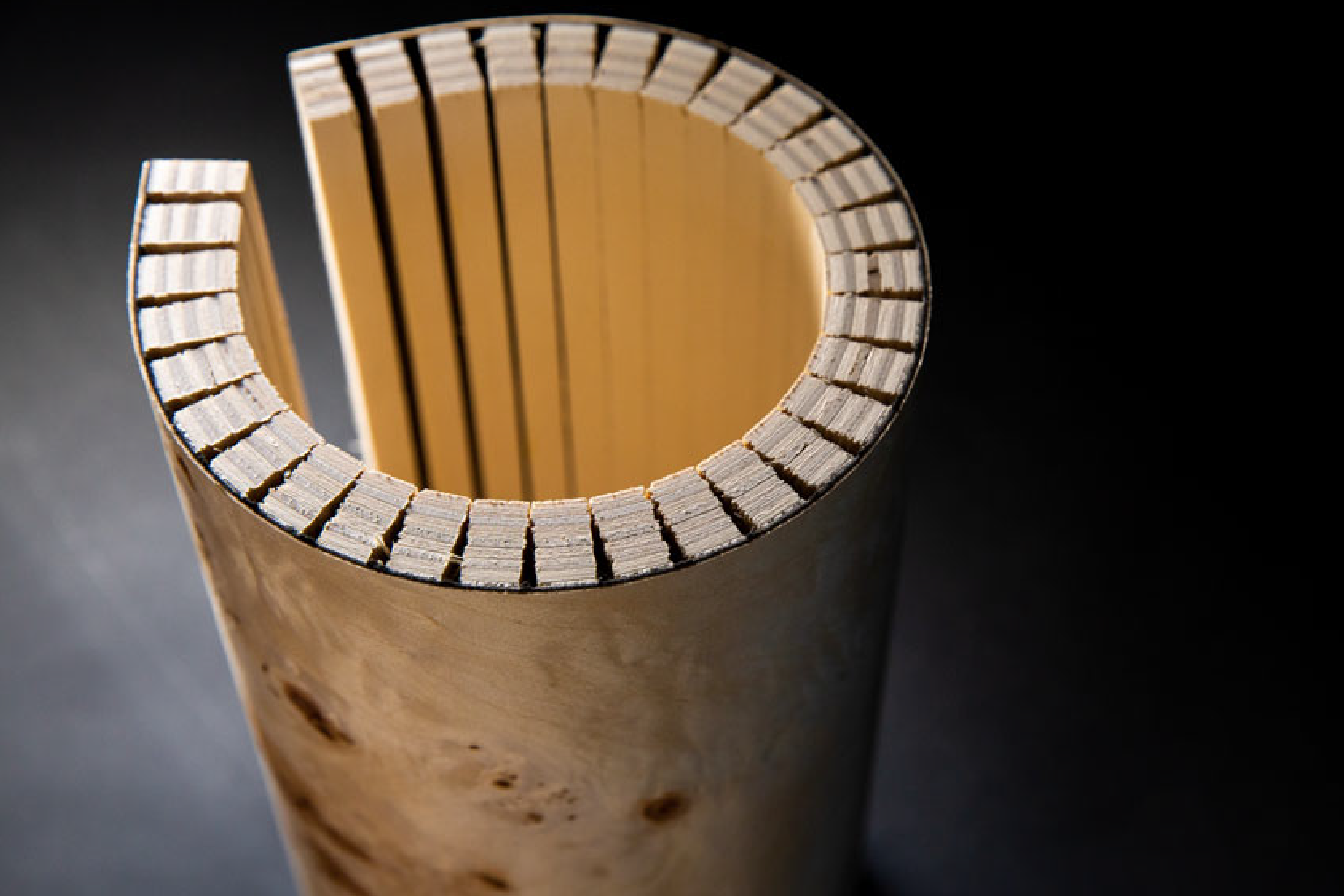

Soflex is a lightweight, flexible panel that strikes the perfect balance between strength and pliability, allowing it to conform to complex shapes without compromising integrity. It can reach a maximum bending radius of 3.5”, enabling you to create dynamic curves.

This unique combination enables quick and effortless application of high-pressure laminates, veneers, metals, and a variety of other semi-rigid materials. Whether you’re working on high-end custom furniture or high-volume commercial projects, Soflex makes ambitious designs achievable with ease.

Key Benefits of Kerfkore Soflex for Furniture Manufacturers

Design Versatility

Soflex enables smooth, seamless curves that traditional rigid materials simply can’t replicate. From flowing cabinet edges to eye-catching rounded desks, it empowers designers to break free from typical material limitations. This creative flexibility allows manufacturers to cater to diverse customer preferences and deliver standout designs that excel in both form and function.

Streamlined Production

Say goodbye to kerf-cutting and steam bending. With Soflex, shaping curves is a simple, hassle-free process. It cuts down on production time and minimizes the manual labor typically required to create curved components—helping you boost efficiency and hit your deadlines with ease.

Improved Material Efficiency

Waste not, want not. Thanks to its inherent flexibility, Soflex eliminates the need for excessive trimming or reshaping. That means less material waste, lower costs, and a more sustainable manufacturing process. It can also be easily spliced together, eliminating scrap and allowing you to make larger or unique sizes.

Enhanced Durability

Despite being ultra-flexible, Soflex is no pushover. It maintains structural integrity under stress and provides a solid base for laminates, veneers, or surface treatments. The end result? Long-lasting furniture with a polished, high-end look.

Cost Savings

Between reduced labor, faster production, and minimized waste, Kerfkore Soflex makes a serious case for cost-effectiveness. It helps manufacturers save on materials, time, and effort—all while delivering a premium-quality product.

Overall

A major manufacturing advantage lies in the ability to laminate the panel while it’s flat, then form it into nearly any desired shape. This approach is significantly faster and more efficient than applying laminate to a pre-curved surface, streamlining production. Laminating on a flat surface also increases accuracy and repeatability, ensuring consistent quality across production runs. It eliminates the need to stock pre-shaped components, enabling multiple curve profiles to be created from a single flat inventory. Once formed, the shape locks firmly into place—without the added weight or expense of heavy structural supports.

Applications in Furniture Manufacturing

Kerfkore Soflex is a versatile choice for many furniture sectors, including:

- Custom Curved Furniture – Great for bespoke, high-design pieces with complex contours.

- Commercial Furniture – Add visual interest to reception areas, workstations, and collaborative spaces.

- Cabinetry & Storage – Elevate modern cabinetry with elegant curves and rounded edges.

- Hospitality Design – Deliver striking and durable designs for restaurants, lounges, and hotels.

Why Choose Kerfkore Soflex?

In an industry that often pits speed against creativity, Soflex offers the best of both worlds. It empowers manufacturers to build faster and dream bigger—without compromise. With the rising demand for custom, sustainable, and eye-catching furniture, Soflex is the forward-thinking material that keeps you ahead of the curve (pun intended).