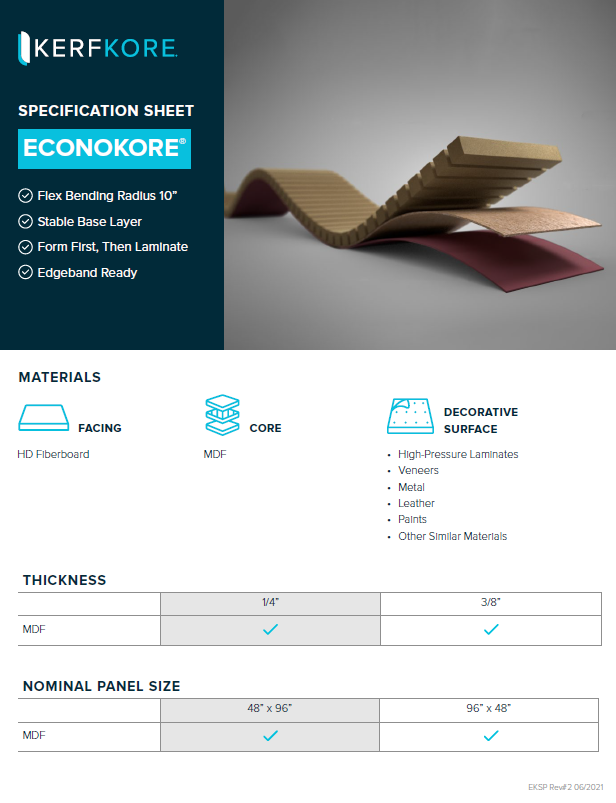

ECONOKORE

ECONOKORE Overview

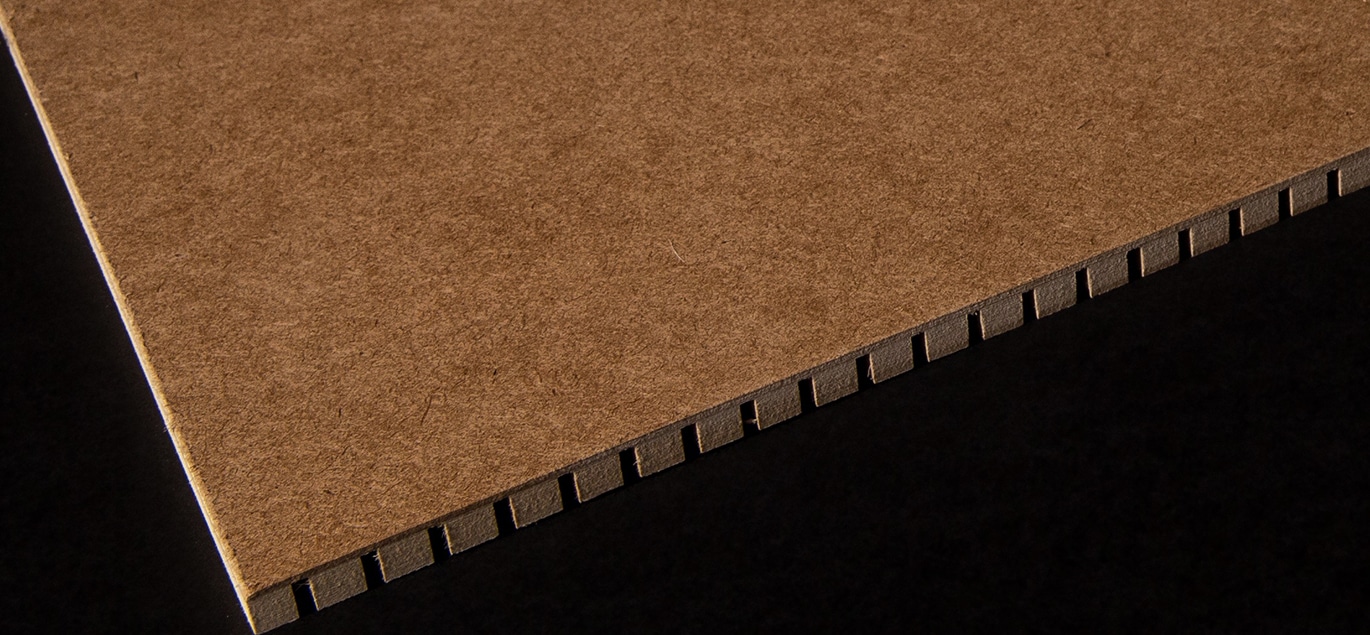

Kerfkore’s Econokore flexible panel combines our unique base layer manufacturing process with a 2-ply product design for a flexible and stable base layer that allows for easy attachment of high-pressure laminates, veneers, metals and many other semirigid materials. When using Econokore, the decorative surfacing material is applied after the base material has been formed into the desired shape achieving a tightest radius of 12″.

ECONOKORE BENEFITS

HD Fiberboard Face

Stronger and harder than MDF providing the ability to achieve a bending radius of 12″

Consistent Thickness

Sanded and Calibrated for accurate seaming; resulting in a high quality finished product

2-Ply Construction

No warping or twisting

ECONOKORE FAQS

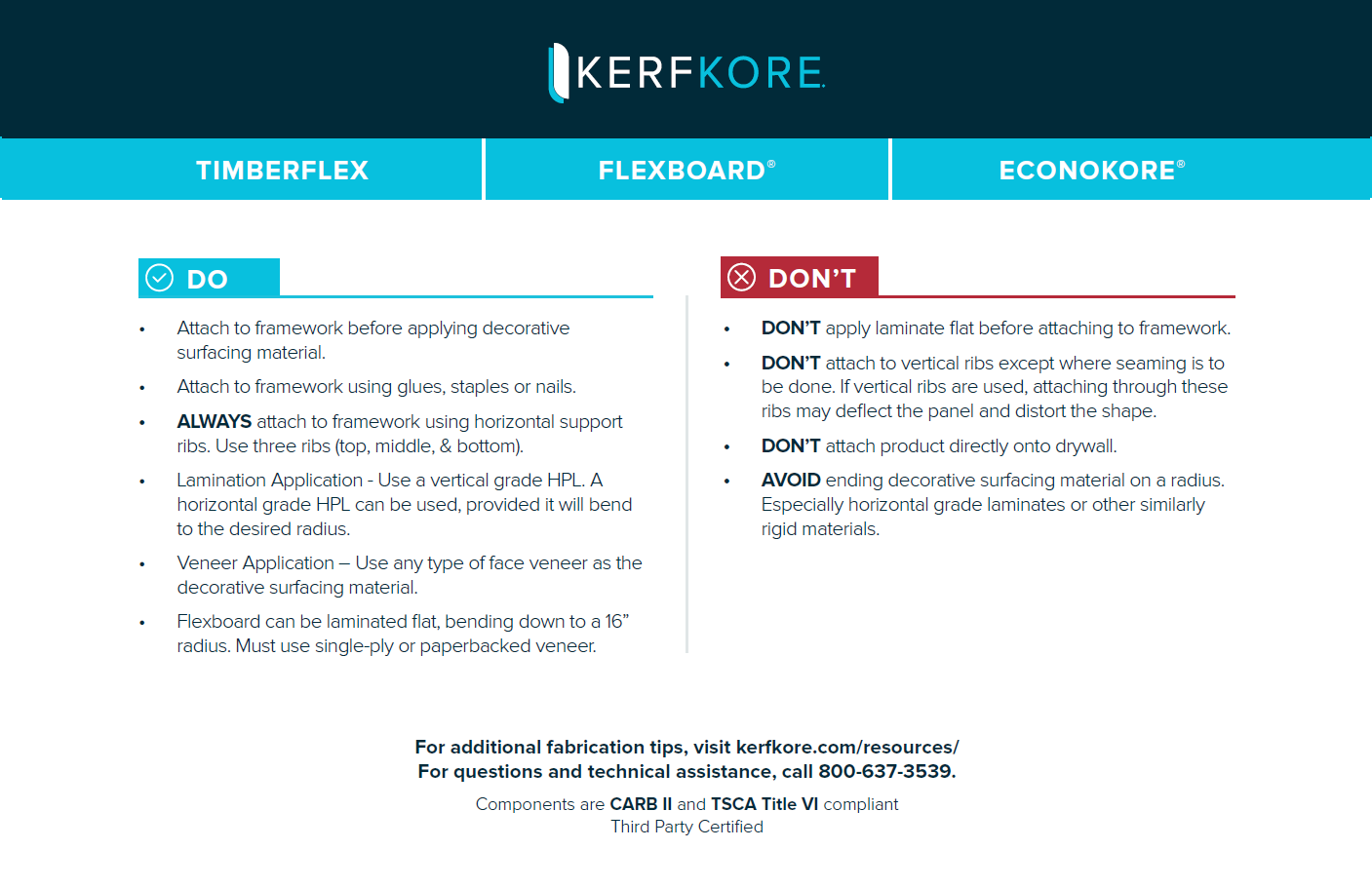

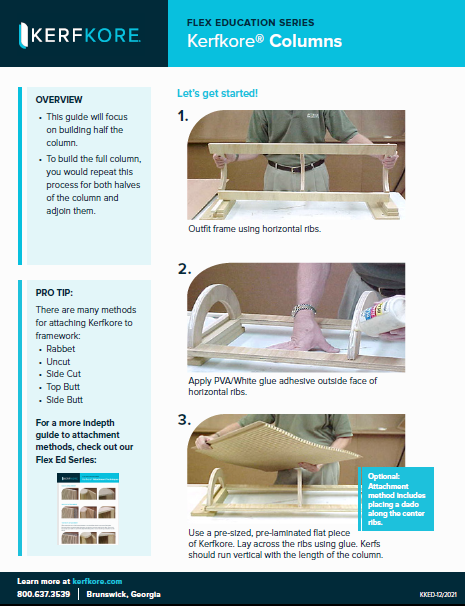

How do I use Econokore?

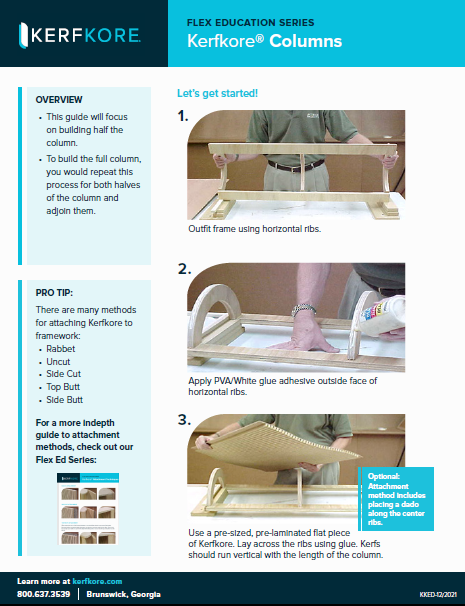

Econokore can be installed using conventional fabrication methods. Laminates and veneers should be applied to Econokore after forming into desired shape.

- Apply the decorative surfacing material using a water or solvent based contact adhesive.

- Ensure uniform adhesion with a J-Roller.

- Allow glue to fully dry according to manufacturers recommendations.

- Use a router to easily trim the decorative surfacing material to match the finished size.

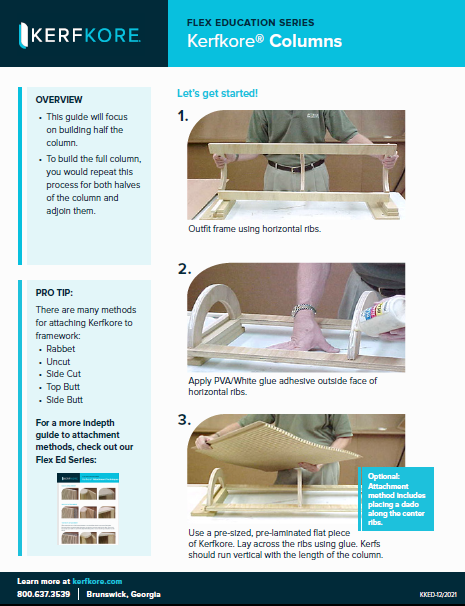

How do I attach Econokore to a framework?

Cut Econokore to match framework. Use a PVA glue and staples to attach the Econokore to the framework.

How do I attach a decorative surfacing material to Econokore?

A suitable contact adhesive is generally the best option.

Can I press a single-ply veneer onto Econokore?

Yes. A single-ply veneer can be attached to Econokore after forming shape.

PRODUCT TESTIMONIAL

"The Kerfkore product line allows our team to focus on what they are really good at doing, rather than dedicating an excessive amount of wasted time on unskilled administrative tasks such as sanding, filling flat areas with Bondo and unnecessary framework. This allows us to offer a better price to our customers."Walton Scott | Quality Cabinet & Fixture Company (San Diego, CA)

REQUEST A SAMPLE