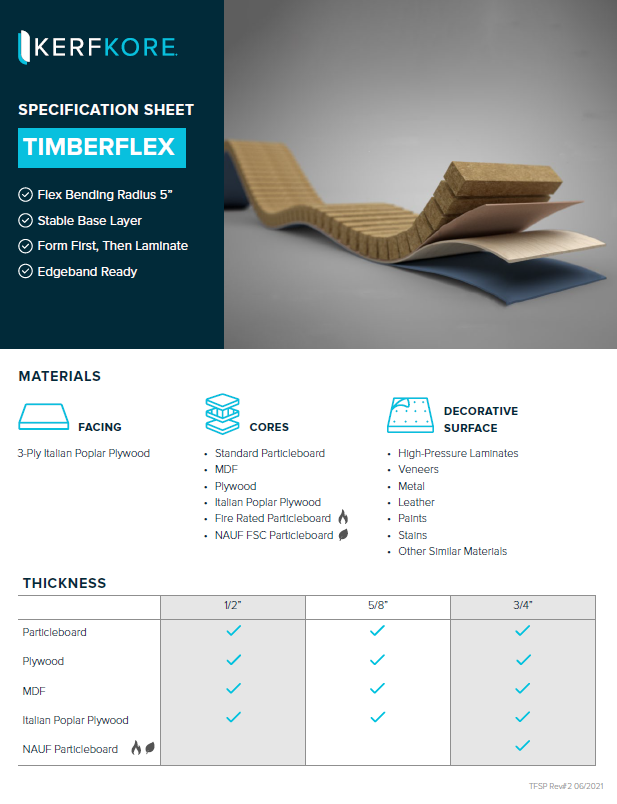

Timberflex

Timberflex Overview

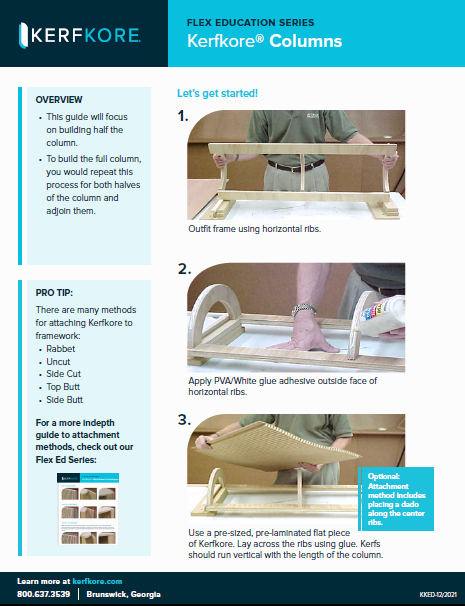

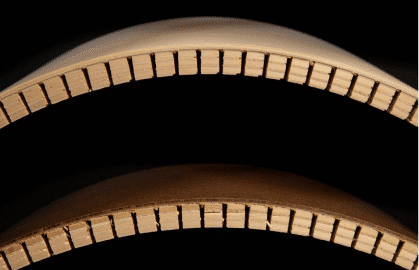

Our Timberflex flexible panel combines our unique base layer manufacturing process with our 1/8″ imported Italian Poplar Plywood Face to create a flexible and extremely stable base layer that allows easy attachment of high-pressure laminates, veneers, metals and many other semirigid materials. When using Timberflex, the decorative surfacing material is applied after the base material has been formed into the desired shape achieving a 5″ radius.

TIMBERFLEX BENEFITS

3-Ply Italian Poplar Plywood Face

Made of overlapped Poplar core veneers whose grains are longitudinally glued and when combined with our Timberflex cores can achieve a smallest radius of 5″.

Dimensionally Sized

Consistent thickness provides excellent seam hiding characteristics and consistent performance and uniformity

Paint, Stain or Laminate - No prep required!

Perfectly flat without dips, valleys, or hard spots eliminating the need for sanding, patching or laying up multiple layers of plywood

TECHNICAL OVERVIEW

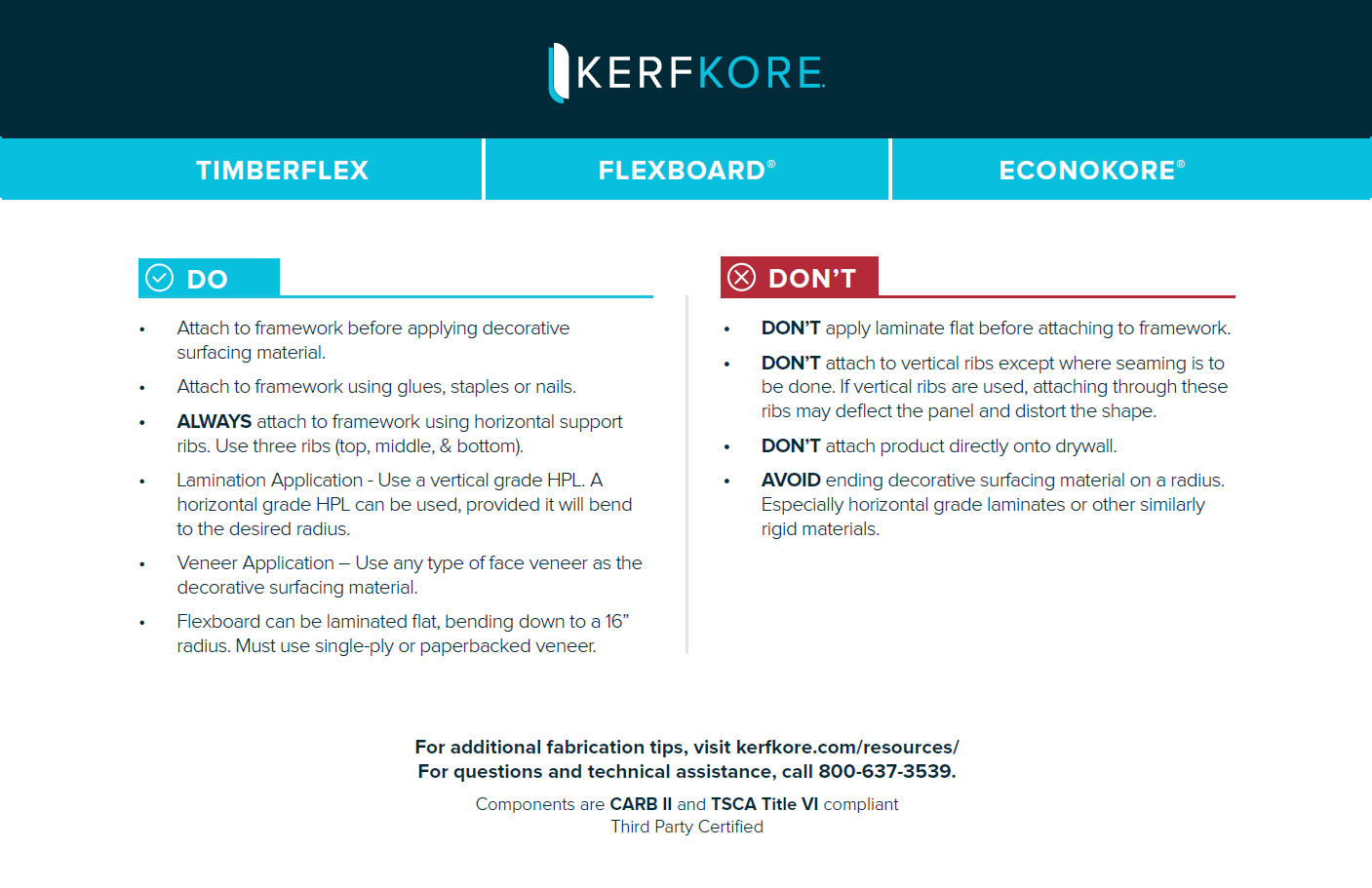

Face Materials

1/8", 3-Ply Italian PoplarCore Materials

Particleboard (ULEF)Plywood

MDF

Italian Poplar Plywood (Premium)

NAF, FR Particleboard

DOWNLOAD SPEC SHEET

TIMBERFLEX FAQS

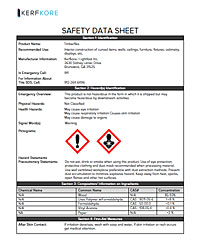

How do I use Timberflex?

Timberflex can be installed using conventional fabrication methods. Laminates and veneers should be applied to Timberflex after forming into desired shape.

- Apply the decorative surfacing material using a water or solvent based contact adhesive

- Ensure uniform adhesion with a J-Roller

- Allow glue to fully dry according manufacturers recommendations.

- Use a router to easily trim the decorative surfacing material to match the finished size.

How do I splice Timberflex?

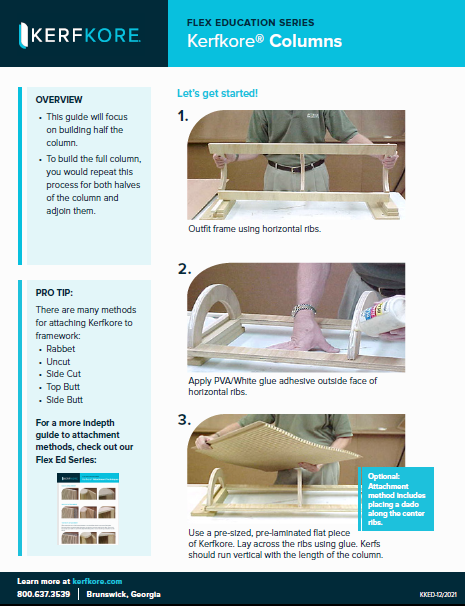

Timberflex cannot be spliced. For a spliceable material, see SoFlex.How do I attach Timberflex flexible panels to a framework?

Cut Timberflex to match framework. Use a PVA glue and staples to attach the Timberflex to the framework.What decorative surfacing materials are recommended for use with Timberflex?

Almost any decorative surfacing material can be used. Options include:

- HPL

- Phenolic backed veneer

- Two-ply veneer

- Three-ply veneer

- Paperbacked veneer

- Metal

- Many other semirigid materials.

- Timberflex’s face can also be stained or painted

PRODUCT TESTIMONIAL

"We saved about four days worth of labor on a recent project by using Timberflex (Over a 70% reduction). Not only did we produce a cleaner product, but we were able to move on to the next project ahead of schedule. We used to kerf our own boards, something that takes time and requires very little skill. Kerfkore Products allowed us to remove this step and focus our skills where they are really needed."Michael Phillips | Mid-American Precast Inc.

REQUEST A SAMPLE