FLEXBOARD

FLEXBOARD Overview

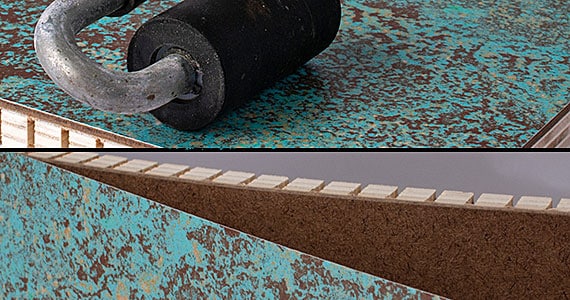

Our Flexboard flexible panel combines our unique base layer manufacturing process with a 0.080″ hardboard face to create a flexible and extremely stable base layer that allows easy attachment of high-pressure laminates, veneers, metals, and many other semirigid materials. When using Flexboard the decorative surfacing material is applied after the base material has been formed into the desired shape achieving an 8″ bending radius.

FLEXBOARD BENEFITS

Laminate Flat or Curved

Laminate flat, then bend to a tight radius of 16″ or laminate after bending to achieve the smallest radius of 8″

100% Recovered & Recycled Fiber

NAF face material and NAF particleboard core material are made from 100% recovered and recycled fiber content.

Paintable - No prep required!

Non oil-based faceboard makes an excellent surface for painting.

TECHNICAL OVERVIEW

Face Materials

Eucalyptus Hardboard (Standard)Core Materials

Particleboard (Standard)

Plywood

MDF

NAUF Particleboard

DOWNLOAD SPEC SHEET

FLEXBOARD FAQS

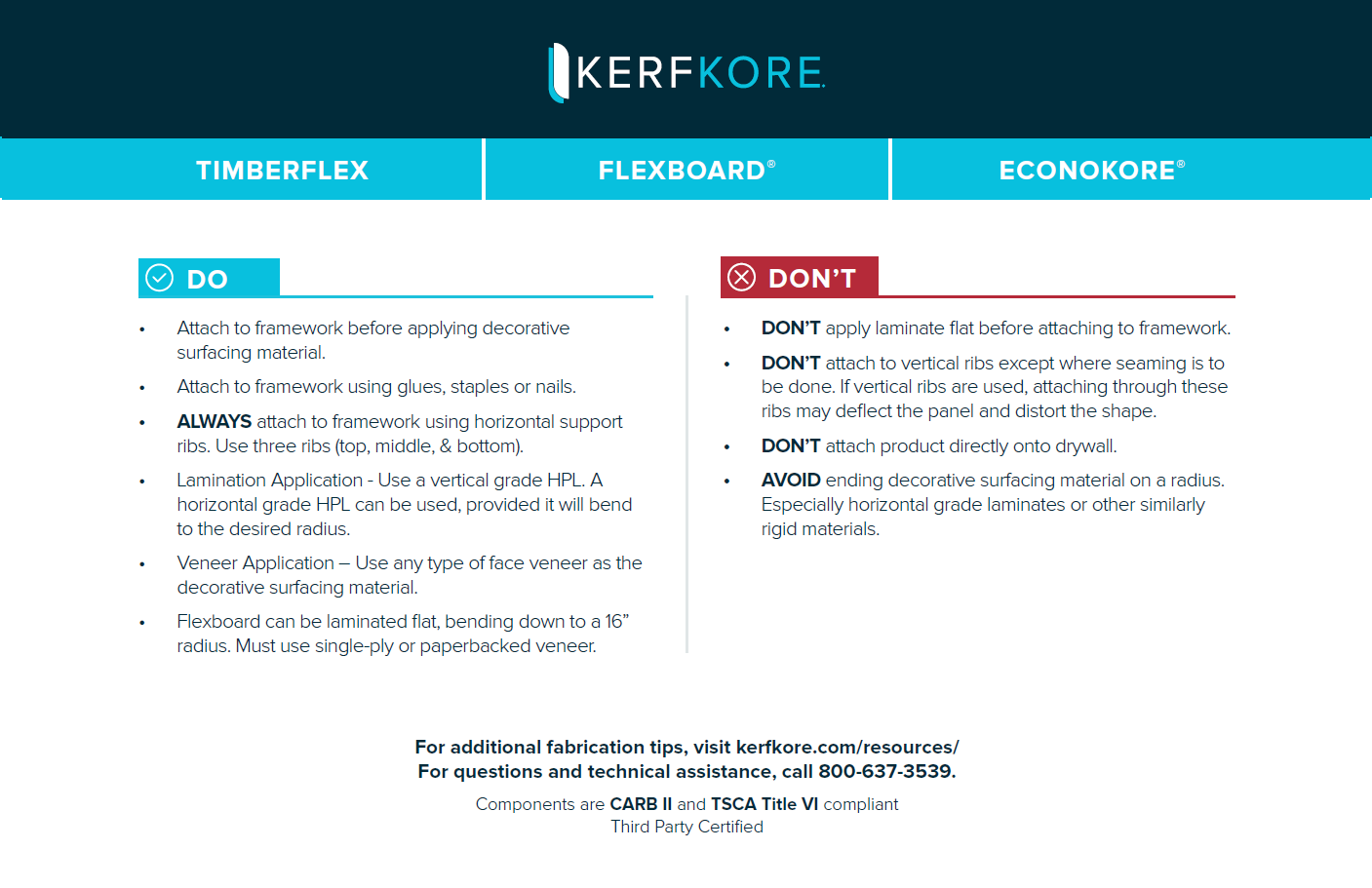

How do I use Flexboard?

Flexboard can be installed using conventional fabrication methods. Laminates and veneers should be applied to Flexboard after forming into the desired shape.

- Apply the decorative surfacing material using a water or solvent based contact adhesive.

- Ensure uniform adhesion with a J-Roller.

- Allow glue to fully dry according to manufacturers recommendations.

- Use a router to easily trim the decorative surfacing material to match the finished size.

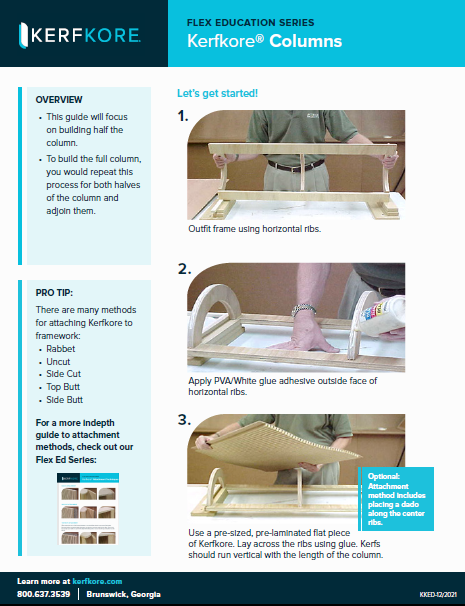

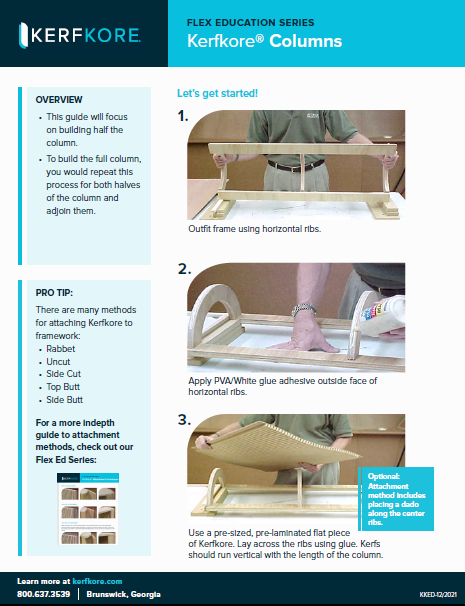

How do I attach Flexboard flexible panels to a framework?

Cut Flexboard to match framework. Use a PVA glue and staples to attach the Flexboard to the framework. Use a hot melt adhesive to help secure the parts until the PVA glue can cure.Can I press a single-ply veneer onto Flexboard?

Yes. A single-ply veneer can be attached to the Flexboard before forming shape. Use a cold press application with a minimum pressure of 125psi. A bending radius of 16″ may be obtainable using this process.The hardboard face on Flexboard looks too slick to attach a face. Is a certain type of glue recommended?

Flexboard does not use an oil-based hardboard face, contact adhesives and PVA glues are both great options.

PRODUCT TESTIMONIAL

"R.B. Woodcraft's task was to fabricate a custom museum environment in a large studio glass show. Our success in creating the display components was facilitated by the use of a number of Kerfkore products including Kerfkore, Timberflex, Flexboard, and Worklite. The variety of lengths, thickness, and bending tolerances helped us meet all the design and engineering challenges that this project presented."Gary Zarnowski | Project Manager, RB Woodcraft

REQUEST A SAMPLE